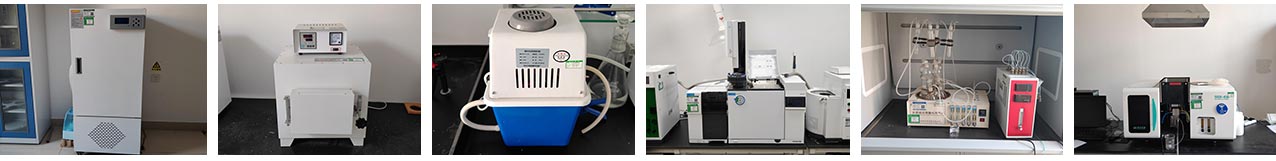

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

-

01-04

-

11-13

-

12-28

-

12-29

-

12-28

-

12-15

-

03-07

-

11-10

-

11-14

-

12-14

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

06-11

-

12-26

-

02-20

-

12-27

-

02-21

-

02-20

-

01-27

-

12-26

-

02-21

-

02-28

-

02-20

-

12-29

-

02-11

-

02-21

-

02-12

-

01-31