宏观检测标准相关信息

GB/T 26956-2011 金属材料焊缝破坏性试验.宏观和微观检验用侵蚀剂

简介:本标准规定了依据ISO 17639:2003(E)金属材料焊缝破坏性试验宏观和微观检验方法对以下材料的焊接接头进行宏观和微观检验常用侵蚀剂。 ——碳钢和低合金钢; ——不锈钢; ——镍及镍合金; ——钛及钛合金; ——铜及铜合金; ——铝及铝合金。本标准适用于金属材料焊缝宏观和微观检验用侵蚀剂。

信息:ICS:25.160.40 CCS:J33 发布:2011-09-29 实施:2012-03-01

ASTM E965-15(2019) 使用体积技术测量路面宏观深度的标准测试方法

简介:

信息:ICS:93.080.20 CCS: 发布:2019-12-01 实施:

EN ISO/TR 16060-2014 金属材料焊接的破坏性测试.宏观与微观检测所需蚀刻剂

简介:

信息:ICS:25.160.40 CCS:H25 发布:2014-08-01 实施:

GB/T 26955-2011 金属材料焊缝破坏性试验.焊缝宏观和微观检验

简介:本标准规定了金属材料焊缝宏观和微观检验的术语和定义、原理、检验目的、试样的截取、检验程序及检验报告。本标准适用于金属材料焊缝的宏观和微观检验。

信息:ICS:25.160.40 CCS:J33 发布:2011-09-29 实施:2012-03-01

ASTM D7723-18 橡胶性能的标准试验方法&x2014;填料在化合物中的宏观分散

简介:

信息:ICS:87.060.10 CCS: 发布:2018-11-01 实施:

JIS G0556-2014 钢的宏观条痕试验方法

简介:This Standard specifies a step-down test method, blue fracture test method and magnetic particle inspection method to assess the non-metallic inclusions in rolled or forged steel with the naked eye or using a magnifying glass with a magnification of not more than×10.

信息:ICS:77.040.99 CCS:H23 发布:2014-03-20 实施:

GB/T 16840.1-2008 电气火灾痕迹物证技术鉴定方法.第1部分:宏观法

简介:GB/T 16840的本部分规定了电气火灾痕迹物证技术鉴定方法——宏观法的定义、原理、仪器、试样、方法步骤和判据。本部分适用于在火灾原因调查时,对火灾现场提取的铜、铝导线熔痕,根据外观特征或熔珠截面孔洞内表面形态特征进行技术鉴定,鉴定其熔化性质。

信息:ICS:13.220 CCS:C82 发布:2008-07-02 实施:2009-05-01

QX/T 421-2018 飞机人工增雨(雪)作业宏观记录规范

简介:

信息:ICS:07.060 CCS:A 47 发布:2018-04-28 实施:2018-08-01

JIS G0556-2014 钢的宏观条痕试验方法

简介:This Standard specifies a step-down test method, blue fracture test method and magnetic particle inspection method to assess the non-metallic inclusions in rolled or forged steel with the naked eye or using a magnifying glass with a magnification of not more than×10.

信息:ICS:77.040.99 CCS:H23 发布:2014-03-20 实施:

GB/T 18023-2000 烟煤的宏观煤岩类型分类

简介: 本标准规定了烟煤宏观煤岩类型的分类以及描述内容和要求。 本标准适用于煤层、煤心和煤标本的观察研究。无烟煤亦可参照使用。

信息:ICS:73.040 CCS:D26 发布:2000-03-16 实施:2000-12-01

ASTM D7723-17 橡胶性能的标准试验方法&x2014;填料在化合物中的宏观分散

简介:

信息:ICS:87.060.10 CCS: 发布:2017-12-01 实施:

ASTM A561-08(2014) 工具钢棒宏观腐蚀试验的标准实施规程

简介:

信息:ICS:77.140.60 CCS: 发布:2014-03-01 实施:

GB 16840.1-1997 电气火灾原因技术鉴定方法 第1部分;宏观法

简介: 本标准规定了定义、原理、设备器材、方法步骤、判定和送检及鉴定时应履行的书面程序。本标准适用于在调查电气火灾原因时,从铜铝导线熔痕外观特征上,鉴定其熔化原因与火灾原因的关系。

信息:ICS:13.220 CCS:C82 发布:1997-06-03 实施:1998-05-01

IEC 60793-1-47:2017 RLV 光纤第1-47部分:测量方法和试验程序宏观弯曲损耗

简介:

信息:ICS:33.180.10 CCS: 发布:2017-10-11 实施:

GOST 33189-2014 牵引式主铁路车辆的传动式齿轮传动装置. 宏观和围观结构的参考标度

简介:

信息:ICS:45.040 CCS:S33 发布:2014 实施:2015-07-01

ASTM E381-22 钢筋、钢坯、初轧坯和锻件宏观浸蚀试验的标准方法

简介:

信息:ICS:77.140.85 CCS: 发布:2022-06-01 实施:

IEC 60793-1-47-2017 RLV 光纤第1-47部分:测量方法和试验程序宏观弯曲损耗

简介:

信息:ICS:33.180.10 CCS: 发布:2017-10-11 实施:

GOST 33189-2014 牵引式主铁路车辆的传动式齿轮传动装置. 宏观和围观结构的参考标度

简介:

信息:ICS:45.040 CCS: 发布:2014 实施:2015-07-01

ISO 4968-2022 钢.硫印宏观检验(鲍曼法)

简介:

信息:ICS:77.040.99 CCS: 发布:2022-04-04 实施:

ASTM E381-17 钢筋、钢坯、钢坯和锻件宏观浸蚀试验的标准方法

简介:

信息:ICS:77.140.85 CCS: 发布:2017-06-01 实施:

GOST 32773-2014 "铁路机车用全轧制轮, 轮胎和轧制轮心. 宏观结构规模标准"

简介:

信息:ICS:45.060.01 CCS: 发布:2014 实施:2015-06-01

ASTM A604/A604M-07(2022) 自耗电极重熔钢筋和钢坯的宏观腐蚀试验的标准实施规程

简介:

信息:ICS:77.140.60 CCS: 发布:2022-03-01 实施:

BS ISO 18550-2016 精细陶瓷 (高级陶瓷, 高级工业陶瓷). 微观结构宏观异质性的试验方法

简介:

信息:ICS:81.060.30 CCS:Q32 发布:2016-03-31 实施:2016-03-31

LST EN ISO 17639-2013 金属材料焊接的破坏试验. 焊接的宏观和微观检验(ISO 17639-2003)

简介:

信息:ICS:25.160.40 CCS: 发布:2013-12-31 实施:2013-12-31

ISO 17639-2022 金属材料焊缝的破坏性试验.焊缝的宏观和微观检验

简介:

信息:ICS:25.160.40 CCS: 发布:2022-02-07 实施:

ISO 18550:2016 精细陶瓷(先进陶瓷 先进技术陶瓷) - 微观结构宏观异质性试验方法

简介:

信息:ICS:81.060.30 CCS: 发布:2016-03-04 实施:

KS L ISO 8486-1-2013(2018) 粘结研磨剂 - 粒度分布的测定和指定 - 第1部分:宏观研磨F4至F220

简介:

信息:ICS:25.100.70 CCS: 发布:2013-12-19 实施:

KS B 0854-2021 点焊接头截面宏观试验方法

简介:

信息:ICS:25.160.40 CCS: 发布:2021-12-30 实施:

ISO 18550-2016 精细陶瓷 (高级陶瓷, 高级工业陶瓷). 微观结构宏观异质性的试验方法

简介:

信息:ICS:81.060.30 CCS:Q32 发布:2016-03 实施:

DIN EN ISO 17639-2013 金属材料焊接的破坏试验. 焊接的宏观和微观检查(ISO 17639-2003); 德文版本EN ISO 17639-2013

简介:

信息:ICS:25.160.40 CCS:J33 发布:2013-12 实施:

DB14/T 2384-2021 地震宏观观测技术规范

简介:本文件规定了地震宏观观测的测报点建设、类型及条件和异常核实。 本文件适用于地震的宏观观测。

信息:ICS:91.120.25 CCS:P 15 发布:2021-12-28 实施:2022-02-28

ISO 4969-2015 钢材. 宏观检验用蚀刻法

简介:

信息:ICS:77.040.99 CCS:H11 发布:2015-08 实施:

BS EN ISO 17639-2013 金属材料焊接的破坏试验. 焊接的宏观和微观检查

简介:

信息:ICS:25.160.40 CCS:J33 发布:2013-11-30 实施:2013-11-30

ASTM E1180-08(2021) 宏观结构评估用硫印刷品制备的标准实施规程

简介:

信息:ICS:71.060.10 CCS: 发布:2021-09-01 实施:

ISO 4969:2015 钢 - 蚀刻方法用于宏观检查

简介:

信息:ICS:77.040.99 CCS: 发布:2015-06-19 实施:

ASTM E340-13 金属和合金宏观腐蚀的标准试验方法

简介:

信息:ICS:77.040.99 CCS: 发布:2013-06-01 实施:

DB1410/T 110-2020 地震宏观观测网建设和管理要求

简介:

信息:ICS:91.120.25 CCS:?P15 发布:2020-12-02 实施:2020-12-02

ASTM D7582-15 通过宏观热重分析对煤焦可乐近似分析的标准试验方法

简介:

信息:ICS:73.040 CCS: 发布:2015-05-15 实施:

CB/T 3380-2013 船用钢材焊接接头宏观组织及缺欠酸蚀试验方法

简介:本标准规定了船用钢材焊接接头宏观组织及缺欠酸蚀试验的试样制备、试验设备、试验方法和试样评定及处理。本标准适用于船用碳素结构钢、低合金结构钢、奥氏体不锈钢、奥氏体+铁素体双相不锈钢、Invar钢的焊接接头宏观酸蚀试验。异种钢焊接接头和其他船用钢材及海洋平台用钢的焊接接头宏观酸蚀试验也可参照使用。

信息:ICS:47.020.05 CCS:U05 发布:2013-04-25 实施:2013-09-01

DB1410/T 110-2020 地震宏观观测网建设和管理要求

简介:

信息:ICS:91.120.25 CCS:?P15 发布:2020-12-02 实施:2020-12-02

ASTM E1845-15 计算路面宏观纹理平均轮廓深度的标准实践

简介:

信息:ICS:17.040.20 CCS: 发布:2015-05-01 实施:

ASTM E340-2013 金属和合金宏观腐蚀的标准试验方法

简介: 3.1x00a0;Applications of Macroetching : 3.1.1x00a0;Macroetching is used to reveal the heterogeneity of metals and alloys. Metallographic specimens and chemical analyses will provide the necessary detailed information about specific localities but they cannot give data about variation from one place to another unless an inordinate number of specimens are taken. 3.1.2x00a0;Macroetching, on the other hand, will provide information on variations in (1) structure, such as grain size, flow lines, columnar structure, dendrites, etc.; (2) variations in chemical composition as evidenced by segregation, carbide and ferrite banding, coring, inclusions, and depth of carburization or decarburization. The information provided about variations in chemical composition is strictly qualitative but the location of extremes in segregation will be shown. Chemical analyses or other means of determining the chemical composition would have to be performed to determine the extent of variation. Macroetching will also show the presence of discontinuities and voids, such as seams, laps, porosity, flakes, bursts, extrusion rupture, cracks, etc. 3.1.3x00a0;Other applications of macroetching in the fabrication of metals are the study of weld structure, definition of weld penetration, dilution of filler metal by base metals, entrapment of flux, porosity, and cracks in weld and heat affected zones, etc. It is also used in the heat-treating shop to determine location of hard or soft spots, tong marks, quenching cracks, case depth in shallow-hardening steels, case depth in carburization of dies, effectiveness of stop-off coatings in carburization, etc. In the machine shop, it can be used for the determination of grinding cracks in tools and dies. 3.1.4x00a0;Macroetching is used extensively for quality control in the steel industry, to determine the tone of a heat in billets with respect to inclusions, segregation, and structure. Forge shops, in addition, use macroetching to reveal flow lines in setting up the best forging practice, die design, and metal flow. For an example of the use of macroetching in the steel forging industry see Method E381. Forging shops and foundries also use macroetching to determine the presence of internal faults and surface defects. The copper industry uses macroetching for control of surface porosity in wire bar. In the aluminum industry, macroetching is used to evaluate extrusions as well as the other products such as forgings, sheets, etc. Defects such as coring, cracks, and porthole die welds are identified. 1.1x00a0;These test procedures describe the methods of macroetching metals and alloys to reveal their macrostructure. 1.2x00a0;The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.3x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.2, 7.1, 8.1.3, 8.2.1, 8.8.3, 8.10.1.1, and 8.13.2.

信息:ICS:77.040.99 (Other methods of testing metals) CCS: 发布:2013 实施:

ISO/TS 18621-21:2020 印刷技术印刷品图像质量评价方法第21部分:用扫描分光光度计测量宏观均匀性的一维畸变

简介:

信息:ICS:37.100.10 CCS: 发布:2020-11-20 实施:

ASTM E965-15 使用体积技术测量路面宏观深度的标准测试方法

简介:

信息:ICS:93.080.20 CCS: 发布:2015-05-01 实施:

ASTM D7582-12 通过宏观热重分析对煤焦可乐近似分析的标准试验方法

简介:

信息:ICS:73.040 CCS: 发布:2012-11-01 实施:

ISO/TS 18621-21-2020 图形技术. 印刷品的图像质量评估方法. 第21部分: 利用扫描分光光度计测量宏观均匀度的一维畸变

简介:

信息:ICS:37.100.10 CCS: 发布:2020-11-00 实施:

ASTM E2157-15 用圆形轨道计测量路面宏观结构特性的标准试验方法

简介:

信息:ICS:93.080.20 CCS: 发布:2015-05-01 实施:

ASTM E381-01(2012) 钢筋、钢坯、钢坯和锻件宏观浸蚀试验的标准方法

简介:

信息:ICS:77.140.85 CCS: 发布:2012-10-01 实施:

ASTM D8339-20 用宏观热重分析法分析烟气脱硫固体的标准试验方法

简介:

信息:ICS:13.040.01 CCS: 发布:2020-07-01 实施:

ASTM E340-2015 金属和合金宏观腐蚀的标准实施规程

简介: 3.1x00a0;Applications of Macroetching:x00a0; 3.1.1x00a0;Macroetching is used to reveal the heterogeneity of metals and alloys. Metallographic specimens and chemical analyses will provide the necessary detailed information about specific localities but they cannot give data about variation from one place to another unless an inordinate number of specimens are taken. 3.1.2x00a0;Macroetching, on the other hand, will provide information on variations in (1) structure, such as grain size, flow lines, columnar structure, dendrites, and so forth; (2) variations in chemical composition as evidenced by segregation, carbide and ferrite banding, coring, inclusions, and depth of carburization or decarburization. The information provided about variations in chemical composition is strictly qualitative but the location of extremes in segregation will be shown. Chemical analyses or other means of determining the chemical composition would have to be performed to determine the extent of variation. Macroetching will also show the presence of discontinuities and voids, such as seams, laps, porosity, flakes, bursts, extrusion rupture, cracks, and so forth. 3.1.3x00a0;Other applications of macroetching in the fabrication of metals are the study of weld structure, definition of weld penetration, dilution of filler metal by base metals, entrapment of flux, porosity, and cracks in weld and heat affected zones, and so forth. It is also used in the heat-treating shop to determine location of hard or soft spots, tong marks, quenching cracks, case depth in shallow-hardening steels, case depth in carburization of dies, effectiveness of stop-off coatings in carburization, and so forth. In the machine shop, it can be used for the determination of grinding cracks in tools and dies. 3.1.4x00a0;Macroetching is used extensively for quality control in the steel industry, to determine the tone of a heat in billets with respect to inclusions, segregation, and structure. Forge shops, in addition, use macroetching to reveal flow lines in setting up the best forging practice, die design, and metal flow. For an example of the use of macroetching in the steel forging industry see Method E381. Forging shops and foundries also use macroetching to determine the presence of internal faults and surface defects. The copper industry uses macroetching for control of surface porosity in wire bar. In the aluminum industry, macroetching is used to evaluate extrusions as well as the other products such as forgings, sheets, and so forth. Defects such as coring, cracks, and porthole die welds are identified. 1.1x00a0;These procedures describe the methods of macroetching metals and alloys to reveal their macrostructure. 1.2x00a0;The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

信息:ICS:77.040.99 CCS: 发布:2015 实施:

ASTM D7582-2012 用宏观热重分析法对煤和焦炭作近似分析的标准试验方法

简介:5. Significance and UseTop Bottom 5.1 Moisture, as determined by this instrumental test method, is used for calculating other analytical results to a dry basis using procedures in Practice D3180. 5.2 Moisture can be used in conjunction with the air-dry moisture loss determined by Test Method D3302 to determine total moisture in coal. Total moisture is used for calculating other analytical results to an as-received basis using Practice D3180. 5.3 Ash yield is the residue remaining after heating the coal and coke samples (see Note 1).Note 1???The ash obtained differs in composition and amount from the mineral constituents present in the original coal. Combustion causes an expulsion of all water, the loss of carbon dioxide from carbonates, the conversion of iron pyrite into iron oxides and sulfur oxides, and other chemical reactions. Ash yield, as determined by this test method, can differ from the amount of ash produced in furnace operations or other combustion systems because combustion conditions influence the chemistry and amount of ash. 5.4 Ash yield is used, (1) as a parameter for evaluating sampling procedures and coal cleaning processes, (2) in the ultimate analysis calculation of oxygen by difference using Practice D3176, (3) in calculations including material balance, reactivity and yields of products relevant to coal conversion processes such as gasification and liquefaction, (4) in calculations to estimate the loading on electrostatic precipitators and on the fly ash and bottom ash disposal systems as well as erosion rates on boiler systems. 5.5 Volatile matter yield, when determined as herein described, may be used to (1) indicate coke yield on carbonization, (2) provide the basis for purchasing and selling, or (3) establish combustion characteristics. 5.6 Fixed carbon is ...........

信息:ICS:73.040 (Coals) CCS: 发布:2012 实施:

ASTM A561-08(2020) 工具钢棒宏观腐蚀试验的标准实施规程

简介:

信息:ICS:77.140.60 CCS: 发布:2020-03-01 实施:

ASTM E965-2015 采用定容技术测量路面宏观结构深度的标准试验方法

简介: 5.1x00a0;This test method is suitable for research and development purposes and for field tests to determine the average macrotexture depth of a pavement surface. The knowledge of pavement macrotexture depth serves as a tool in characterizing the pavement surface texture. When used in conjunction with other physical tests, the macrotexture depth values derived from this test method may be used to determine the pavement skid resistance capability and the suitability of paving materials or finishing techniques. When used with other tests, care should be taken that all tests are applied at the same location. Improvements in pavement finishing practices and maintenance schedules may result from use of this test method. 5.2x00a0;The texture depth measurements produced using this test method are influenced by pavement macrotexture characteristics and not significantly affected by pavement microtexture. Pavement aggregate particle shape, size, and distribution are texture features not addressed in this procedure. This test method is not meant to provide a complete assessment of pavement surface texture characteristics. 5.3x00a0;The pavement macrotexture depth values measured by this test method, with the equipment and procedures stated herein, do not necessarily agree or correlate directly with other techniques of surface texture measurements. Note 2:x00a0;The pavement surface to be measured using this test method must be dry and free of any construction residue, surface debris, and loose aggregate particles that would be displaced or removed during normal environmental and traffic conditions. 1.1x00a0;This test method describes a procedure for determining the average depth of pavement surface macrotexture (see 3.1) (1)2 by careful application of a known volume of material on the surface and subsequent measurement of the total area covered. The technique is designed to provide an average depth value of only the pavement macrotexture and is considered insensitive to pavement microtexture characteristics. 1.2x00a0;The results obtained using this procedure to determine average pavement macrotexture depths do not necessarily agree or correlate directly with those obtained by other pavement macrotexture measuring methods (1-5). 1.3x00a0;The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.4x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to......

信息:ICS: CCS: 发布:2015 实施:

DIN EN 2954-002-2010 航空航天系列.钛及钛合金锻轧材的宏观结构.第002部分:棒材,型材,锻坯及锻件的宏观结构;德文版本和英文版本EN 2954-002-2010

简介:

信息:ICS:49.025.30 CCS:V11 发布:2010-12-01 实施:

ASTM D7723-19 橡胶性能的标准试验方法&x2014;填料在化合物中的宏观分散

简介:

信息:ICS:87.060.10 CCS: 发布:2019-12-01 实施:

ASTM E1180-08(2014) 硫酸印刷准备的宏观结构评估标准实践

简介:

信息:ICS:71.060.10 CCS: 发布:2014-10-01 实施:

DIN EN 13036-1-2010 道路和机场地面特性.试验方法.第1部分:使用体积修补技术测量道路表面宏观结构的深度.德文版本EN 13036-1-2001

简介:

信息:ICS:17.040.20;93.080.10;93.120 CCS:P68 发布:2010-10 实施:

ASTM E965-15(2019) 使用体积技术测量路面宏观深度的标准测试方法

简介:

信息:ICS:93.080.20 CCS: 发布:2019-12-01 实施:

BS PD CEN ISO/TR 16060-2014 金属材料焊接的破坏试验. 宏观和微观检验腐蚀剂

简介:

信息:ICS:25.160.40 CCS:J33 发布:2014-08-31 实施:2014-08-31

NF L10-813-002-2010 航空航天系列.钛及钛合金锻轧材的宏观结构.第002部分:棒材,型材,锻坯及锻件的宏观结构.

简介:

信息:ICS:49.025.30 CCS:V11 发布:2010-09-01 实施:2010-09-04

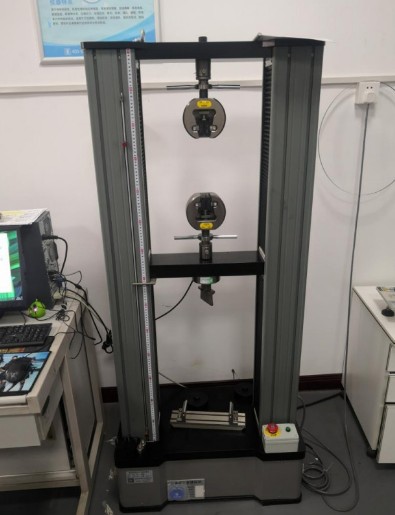

北检院部分仪器展示

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +