平面应变止裂韧度检测标准

发布时间:2023-02-08 18:39:06

点击数:0

平面应变止裂韧度检测标准相关信息

GB/T 19744-2005 铁素体钢平面应变止裂韧度 K Ia 试验方法

简介: 本标准规定了铁素体钢平面应变止裂韧度K试验方法的符号、定义、试样、试验设备、试验程序、试验结果的处理和计算以及试验报告。 本标准适用于侧面开槽,裂纹线楔形加载试样,在裂纹前缘获得拉伸断裂的快速止裂部分;本标准提供了裂纹止裂后短时间内的应力强度因子的静态分析方法。估计值定义为K,当尺寸满足要求时,估计值为该材料的平面应变止裂韧度值K。 本标准适用于室温、低温和高温条件下用紧凑止裂试样(CCA)测定铁素体钢的平面应变止裂韧度K,并提供了评价拉伸断口表面可接受程度的方法和止裂裂纹长度的测定方法(见附录A)。 本标准要求试样平面尺寸足够大,允许对试样进行模拟线弹性分析,厚度要满足平面应变条件。

信息:ICS:77.040.10 CCS:H22 发布:2005-05-13 实施:2005-10-01

ISO 29221:2014 塑料制品;I型平面应变止裂韧度的测定

简介:

信息:ICS:83.080.01 CCS: 发布:2014-01-16 实施:

ASTM E1221-2010 测定铁素体钢的平面应变裂纹止裂断裂韧度KIa 的标准试验方法

简介:In structures containing gradients in either toughness or stress, a crack may initiate in a region of either low toughness or high stress, or both, and arrest in another region of either higher toughness or lower stress, or both. The value of the stress intensity factor during the short time interval in which a fast-running crack arrests is a measure of the ability of the material to arrest such a crack. Values of the stress intensity factor of this kind, which are determined using dynamic methods of analysis, provide a value for the crack-arrest fracture toughness which will be termed KA in this discussion. Static methods of analysis, which are much less complex, can often be used to determine K at a short time (1 to 2 ms) after crack arrest. The estimate of the crack-arrest fracture toughness obtained in this fashion is termed Ka. When macroscopic dynamic effects are relatively small, the difference between KA and Ka is also small (1-4). For cracks propagating under conditions of crack-front plane-strain, in situations where the dynamic effects are also known to be small, KIa determinations using laboratory-sized specimens have been used successfully to estimate whether, and at what point, a crack will arrest in a structure (5, 6). Depending upon component design, loading compliance, and the crack jump length, a dynamic analysis of a fast-running crack propagation event may be necessary in order to predict whether crack arrest will occur and the arrest position. In such cases, values of KIa determined by this test method can be used to identify those values of K below which the crack speed is zero. More details on the use of dynamic analyses can be found in Ref (4). This test method can serve at least the following additional purposes: In materials research and development, to establish in quantitative terms significant to service performance, the effects of metallurgical variables (such as composition or heat treatment) or fabrication operations (such as welding or forming) on the ability of a new or existing material to arrest running cracks. In design, to assist in selection of materials for, and determine locations and sizes of, stiffeners and arrestor plates.1.1 This test method employs a side-grooved, crack-line-wedge-loaded specimen to obtain a rapid run-arrest segment of flat-tensile separation with a nearly straight crack front. This test method provides a static analysis determination of the stress intensity factor at a short time after crack arrest. The estimate is denoted Ka. When certain size requirements are met, the test result provides an estimate, termed KIa, of the plane-strain crack-arrest toughness of the material. 1.2 The specimen size requirements, discussed later, provide for in-plane dimensions large enough to allow the specimen to be modeled by linear elastic analysis. For conditions of plane-strain, a minimum specimen thickness is also required. Both requirements depend upon the crack arrest toughness and the yield strength of the material. A range of specimen sizes may therefore be needed, as specified in this test method. 1.3 If the specimen does not exhibit rapid crack propagation and arrest, K

信息:ICS:77.040.10 CCS:H11 发布:2010 实施:

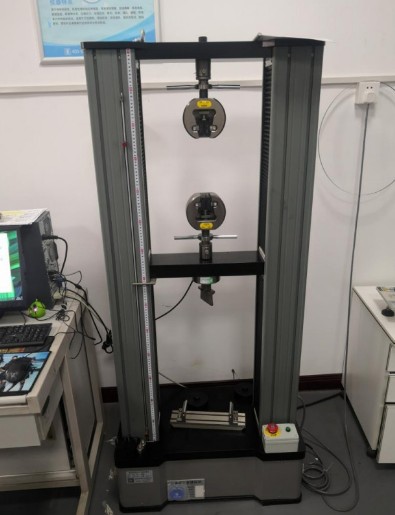

北检院部分仪器展示

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +