不锈钢应力腐蚀检测标准相关信息

GB/T 25996-2019 绝热材料对奥氏体不锈钢外部应力腐蚀开裂的试验方法

简介:

信息:ICS:91.120.10 CCS:Q25 发布:2019-10-18 00:00:00.0 实施:2020-09-01 00:00:00.0

NACE RP0170-2004 奥氏体不锈钢及其它奥氏体合金在炼油设备关停期间防连多硫酸应力腐蚀裂纹的保护.项目编号21002

简介:

信息:ICS: CCS: 发布:2004-03-27 实施:

YB/T 5362-2006 不锈钢在沸腾氯化镁溶液中应力腐蚀试验方法

简介:

信息:ICS: CCS:H25 发布: 实施:2006-10-11

GB/T 25996-2010 绝热材料对奥氏体不锈钢外部应力腐蚀开裂的试验方法

简介:本标准规定了绝热材料对奥氏体不锈钢外部应力腐蚀开裂的试验方法。本标准适用于覆盖奥氏体不锈钢用纤维型绝热材料包括岩棉、矿渣棉、玻璃棉、硅酸铝棉等及其制品,也适用于此用途的其他类型绝热材料如硅酸钙、水泥、复合硅酸盐、泡沫石棉、泡沫塑料、泡沫橡塑等。

信息:ICS:91.100.60 CCS:Q25 发布:2011-01-10 实施:2011-10-01

KS D 0236-2003 不锈钢的应力腐蚀开裂试验方法

简介:이 규격은 스테인리스강의 응력 부식 균열 시험 방법에 대하여 A법:42 % 염화마그네슘

信息:ICS:77.040.30 CCS:H59 发布:2003-04-30 实施:2003-04-30

GB/T 17898-1999 不锈钢在沸腾氯化镁溶液中应力腐蚀试验方法

简介: 本标准规定了不锈钢在恒负荷拉伸,U型弯曲试验条件下试样制备和要求、试验溶液、试验仪器和设备、试验条件和步骤及试验报告。 本标准适用于评价不锈钢在沸腾氯化镁溶液中应力腐蚀敏感性。

信息:ICS:77.060 CCS:H25 发布:1999-11-01 实施:2000-08-01

KS D 0236-2003 不锈钢的应力腐蚀开裂试验方法

简介:이 규격은 스테인리스강의 응력 부식 균열 시험 방법에 대하여 A법:42 % 염화마그네슘

信息:ICS:77.040.30 CCS:H59 发布:2003-04-30 实施:2003-04-30

ASTM G123-00(2022)e1 评估沸腾酸化氯化钠溶液中不同镍含量的不锈钢合金应力腐蚀开裂的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2022-10-01 实施:

KS D 0236-2003(2018) 应力腐蚀开裂不锈钢的测试

简介:

信息:ICS:77.040.30 CCS: 发布:2003-04-30 实施:

ASTM C692-13(2018) 评估绝缘对奥氏体不锈钢外应力腐蚀开裂倾向影响的标准试验方法

简介:

信息:ICS:91.100.60 CCS: 发布:2018-11-01 实施:

JIS G0576-2001 不锈钢的应力腐蚀断裂试验

简介:この規格は,ステンレス鋼の応力腐食割れ試験方法について,A法:42%塩化マグネシウム応力腐食割れ試験方法,及びB法:30 %塩化カルシウム応力腐食割れ試験方法を規定する。

信息:ICS:77.040.30;77.060 CCS:H25 发布:2001-04-20 实施:

ASTM G35-98(2015) 确定不锈钢和相关镍 - 铬 - 铁合金在多硫酸中应力腐蚀开裂的敏感性的标准实践

简介:

信息:ICS:77.040.10 CCS: 发布:2015-11-01 实施:

ASTM G123-00 沸腾酸化氯化钠溶液中不同镍含量不锈钢合金应力腐蚀开裂的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2000-10-10 实施:

ASTM G123-00(2015) 沸腾酸化氯化钠溶液中不同镍含量不锈钢合金应力腐蚀开裂的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2015-11-01 实施:

ASTM C692-00 评估绝缘对奥氏体不锈钢外应力腐蚀开裂倾向影响的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2000-03-10 实施:

ASTM C692-13 评估绝缘对奥氏体不锈钢外应力腐蚀开裂倾向影响的标准试验方法

简介:

信息:ICS:91.100.60 CCS: 发布:2013-05-01 实施:

ASTM C692-2000 评定热绝缘材料对奥氏体不锈钢外部应力腐蚀开裂趋势影响的标准试验方法

简介:1.1 This test method covers two procedures for the laboratory evaluation of thermal insulation materials that may actively contribute to external stress corrosion cracking (ESCC) of austenitic stainless steel due to soluble chlorides within the insulation. It should be understood that this laboratory procedure is not intended to cover all of the possible field conditions that might contribute to ESCC. 1.2 While the 1977 edition of this test method (Dana test) is applicable only to wicking-type insulations, the procedures in this edition are intended to be applicable to all insulating materials, including cements, some of which would disintegrate when tested in accordance with the 1977 edition. Wicking insulations are materials that wet through and through when partially (50 to 75%) immersed in water for a short period of time (10 min or less). 1.3 These procedures are intended primarily as a preproduction test for qualification of the basic chemical composition of a particular manufacturer''s product and are not intended to be routine tests for ongoing quality assurance or production lot compliance. Test Methods C871, on the other hand, is used for confirmation of acceptable chemical properties of subsequent lots of insulation previously found acceptable by this test method. 1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:77.060 (Corrosion of metals) CCS:Q25 发布:2000 实施:

JIS G0576 AMD 1-2012 不锈钢的氯化物溶液应力腐蚀破裂试验(修改件1)

简介:

信息:ICS:77.040.30;77.060 CCS:H25 发布:2012-01-20 实施:

ASTM G123-2000 沸腾酸化氯化钠溶液中不同镍合量不锈钢合金应力腐蚀裂纹评定的标准试验方法

简介:1.1 This test method describes a procedure for conducting stress-corrosion cracking tests in an acidified boiling sodium chloride solution. This test method is performed in 25% (by mass ) sodium chloride acidified to pH 1.5 with phosphoric acid. This test method is concerned primarily with the test solution and glassware, although a specific style of U-bend test specimen is suggested. 1.2 This test method is designed to provide better correlation with chemical process industry experience for stainless steels than the more severe boiling magnesium chloride test of Practice G36. Some stainless steels which have provided satisfactory service in many environments readily crack in Practice G36, but have not cracked during interlaboratory testing using this sodium chloride test method. 1.3 This boiling sodium chloride test method was used in an interlaboratory test program to evaluate wrought stainless steels, including duplex (ferrite-austenite) stainless and an alloy with up to about 33% nickel. It may also be employed to evaluate these types of materials in the cast or welded conditions. 1.4 This test method detects major effects of composition, heat treatment, microstructure, and stress on the susceptibility of materials to chloride stress-corrosion cracking. Small differences between samples such as heat-to-heat variations of the same grade are not likely to be detected. 1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

信息:ICS:77.060 (Corrosion of metals) CCS:H40 发布:2000 实施:

JIS G0576 AMD 1-2012 不锈钢的氯化物溶液应力腐蚀破裂试验(修改件1)

简介:

信息:ICS:77.040.30;77.060 CCS:H25 发布:2012-01-20 实施:

ASTM G123-2000(2011) 沸腾酸化氯化钠溶液中不同镍含量不锈钢合金应力腐蚀裂纹评估的标准试验方法

简介:This test method is designed to compare alloys and may be used as one method of screening materials prior to service. In general, this test method is more useful for stainless steels than the boiling magnesium chloride test of Practice G 36. The boiling magnesium chloride test cracks materials with the nickel levels found in relatively resistant austenitic and duplex stainless steels, thus making comparisons and evaluations for many service environments difficult. This test method is intended to simulate cracking in water, especially cooling waters that contain chloride. It is not intended to simulate cracking that occurs at high temperatures (greater than 200x00B0;C or 390x00B0;F) with chloride or hydroxide. Note 18212;The degree of cracking resistance found in full-immersion tests may not be indicative of that for some service conditions comprising exposure to the water-line or in the vapor phase where chlorides may concentrate. Correlation with service experience should be obtained when possible. Different chloride environments may rank materials in a different order. In interlaboratory testing, this test method cracked annealed UNS S30400 and S31600 but not more resistant materials, such as annealed duplex stainless steels or higher nickel alloys, for example, UNS N08020 (for example 20Cb-34 stainless). These more resistant materials are expected to crack when exposed to Practice G 36 as U-bends. Materials which withstand this sodium chloride test for a longer period than UNS S30400 or S31600 may be candidates for more severe service applications. The repeatability and reproducibility data from Section 12 and Appendix X1 must be considered prior to use. Interlaboratory variation in results may be expected as occurs with many corrosion tests. Acceptance criteria are not part of this test method and if needed are to be negotiated by the user and the producer.1.1 This test method describes a procedure for conducting stress-corrosion cracking tests in an acidified boiling sodium chloride solution. This test method is performed in 25% (by mass ) sodium chloride acidified to pH 1.5 with phosphoric acid. This test method is concerned primarily with the test solution and glassware, although a specific style of U-bend test specimen is suggested. 1.2 This test method is designed to provide better correlation with chemical process industry experience for stainless steels than the more severe boiling magnesium chloride test of Practice G36. Some stainless steels which have provided satisfactory service in many environments readily crack in Practice G36, but have not cracked during interlaboratory testing using this sodium chloride test method. 1.3 This boiling sodium chloride test method was used in an interlaboratory test program to evaluate wrought stainless steels, including duplex (ferrite-austenite) stainless and an alloy with up to about 33% nickel. It may also be employed to evaluate these types of materials in the cast or welded conditions. 1.4 This test method detects major effects of composition, heat treatment, microstructure, and stress on the susceptibility of materials to chloride stress-corrosion cracking. Small differences between samples such as heat-to-heat variations of the same grade are not likely to be detected. 1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard ......

信息:ICS:77.060 CCS:H25 发布:2000 实施:

ASTM G123-00(2011) 沸腾酸化氯化钠溶液中不同镍含量不锈钢合金应力腐蚀开裂的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2011-03-01 实施:

ASTM G123-2000(2015) 沸腾酸化氯化钠溶液中不同镍合金含量不锈钢合金应力腐蚀裂纹评定的标准试验方法

简介: 5.1x00a0;This test method is designed to compare alloys and may be used as one method of screening materials prior to service. In general, this test method is more useful for stainless steels than the boiling magnesium chloride test of Practice G36. The boiling magnesium chloride test cracks materials with the nickel levels found in relatively resistant austenitic and duplex stainless steels, thus making comparisons and evaluations for many service environments difficult. 5.2x00a0;This test method is intended to simulate cracking in water, especially cooling waters that contain chloride. It is not intended to simulate cracking that occurs at high temperatures (greater than 200x00b0;C or 390x00b0;F) with chloride or hydroxide. Note 1:x00a0;The degree of cracking resistance found in full-immersion tests may not be indicative of that for some service conditions comprising exposure to the water-line or in the vapor phase where chlorides may concentrate. 5.3x00a0;Correlation with service experience should be obtained when possible. Different chloride environments may rank materials in a different order. 5.4x00a0;In interlaboratory testing, this test method cracked annealed UNS S30400 and S31600 but not more resistant materials, such as annealed duplex stainless steels or higher nickel alloys, for example, UNS N08020 (for example 20Cb-34 stainless). These more resistant materials are expected to crack when exposed to Practice G36 as U-bends. Materials which withstand this sodium chloride test for a longer period than UNS S30400 or S31600 may be candidates for more severe service applications. 5.5x00a0;The repeatability and reproducibility data from Section 12 and Appendix X1 must be considered prior to use. Interlaboratory variation in results may be expected as occurs with many corrosion tests. Acceptance criteria are not part of this test method and if needed are to be negotiated by the user and the producer. 1.1x00a0;This test method covers a procedure for conducting stress-corrosion cracking tests in an acidified boiling sodium chloride solution. This test method is performed in 258201;% (by mass) sodium chloride acidified to pH 1.5 with phosphoric acid. This test method is concerned primarily with the test solution and glassware, although a specific style of U-bend test specimen is suggested. 1.2x00a0;This test method is designed to provide better correlation with chemical process industry experience for stainless steels than the more severe boiling magnesium chloride test of Practice G36. Some stainless steels which have provided satisfactory service in many environments readily crack in Practice G36, but have not cracked during interlaboratory testing (see Section 12) using this sodium ......

信息:ICS:77.060 CCS: 发布:2000 实施:

ASTM G35-98(2010) 确定不锈钢和相关镍 - 铬 - 铁合金在多硫酸中应力腐蚀开裂的敏感性的标准实践

简介:

信息:ICS:77.040.10 CCS: 发布:2010-09-01 实施:

ASTM G123-2000(2005) 沸腾酸化氯化钠溶液中不同镍合量不锈钢合金应力腐蚀裂纹评定的标准试验方法

简介:This test method is designed to compare alloys and may be used as one method of screening materials prior to service. In general, this test method is more useful for stainless steels than the boiling magnesium chloride test of Practice G 36. The boiling magnesium chloride test cracks materials with the nickel levels found in relatively resistant austenitic and duplex stainless steels, thus making comparisons and evaluations for many service environments difficult. This test method is intended to simulate cracking in water, especially cooling waters that contain chloride. It is not intended to simulate cracking that occurs at high temperatures (greater than 200x00B0;C or 390x00B0;F) with chloride or hydroxide. Note 18212;The degree of cracking resistance found in full-immersion tests may not be indicative of that for some service conditions comprising exposure to the water-line or in the vapor phase where chlorides may concentrate. Correlation with service experience should be obtained when possible. Different chloride environments may rank materials in a different order. In interlaboratory testing, this test method cracked annealed UNS S30400 and S31600 but not more resistant materials, such as annealed duplex stainless steels or higher nickel alloys, for example, UNS N08020 (for example 20Cb-34 stainless). These more resistant materials are expected to crack when exposed to Practice G 36 as U-bends. Materials which withstand this sodium chloride test for a longer period than UNS S30400 or S31600 may be candidates for more severe service applications. The repeatability and reproducibility data from Section 12 and Appendix X1 must be considered prior to use. Interlaboratory variation in results may be expected as occurs with many corrosion tests. Acceptance criteria are not part of this test method and if needed are to be negotiated by the user and the producer.1.1 This test method describes a procedure for conducting stress-corrosion cracking tests in an acidified boiling sodium chloride solution. This test method is performed in 25% (by mass ) sodium chloride acidified to pH 1.5 with phosphoric acid. This test method is concerned primarily with the test solution and glassware, although a specific style of U-bend test specimen is suggested. 1.2 This test method is designed to provide better correlation with chemical process industry experience for stainless steels than the more severe boiling magnesium chloride test of Practice G36. Some stainless steels which have provided satisfactory service in many environments readily crack in Practice G36, but have not cracked during interlaboratory testing using this sodium chloride test method. 1.3 This boiling sodium chloride test method was used in an interlaboratory test program to evaluate wrought stainless steels, including duplex (ferrite-austenite) stainless and an alloy with up to about 33% nickel. It may also be employed to evaluate these types of materials in the cast or welded conditions. 1.4 This test method detects major effects of composition, heat treatment, microstructure, and stress on the susceptibility of materials to chloride stress-corrosion cracking. Small differences between samples such as heat-to-heat variations of the same grade are not likely to be detected. 1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard ......

信息:ICS:77.060 (Corrosion of metals) CCS:H40 发布:2000 实施:

ASTM C692-08e1 评估绝缘对奥氏体不锈钢外应力腐蚀开裂倾向影响的标准试验方法

简介:

信息:ICS:91.100.60 CCS: 发布:2008-10-01 实施:

ASTM G35-1998(2010) 测定不锈钢及有关镍铬铁合金在连多硫酸中应力腐蚀断裂灵敏性的标准操作规程

简介:This environment provides a way of evaluating the resistance of stainless steels and related alloys to intergranular stress corrosion cracking. Failure is accelerated by the presence of increasing amounts of intergranular precipitate. Results for the polythionic acid test have not been correlated exactly with those of intergranular corrosion tests. Also, this test may not be relevant to stress corrosion cracking in chlorides or caustic environments. The polythionic acid environment may produce areas of shallow intergranular attack in addition to the more localized and deeper cracking mode of attack. Examination of failed specimens is necessary to confirm that failure occurred by cracking rather than mechanical failure of reduced sections.1.1 This practice covers procedures for preparing and conducting the polythionic acid test at room temperature, 22 to 25x00B0;C (72 to 77x00B0;F), to determine the relative susceptibility of stainless steels or other related materials (nickel-chromiumiron alloys) to intergranular stress corrosion cracking. 1.2 This practice can be used to evaluate stainless steels or other materials in the x201C;as receivedx201D; condition or after being subjected to high-temperature service, 482 to 815x00B0;C (900 to 1500x00B0;F), for prolonged periods of time. 1.3 This practice can be applied to wrought products, castings, and weld metal of stainless steels or other related materials to be used in environments containing sulfur or sulfides. Other materials capable of being sensitized can also be tested in accordance with this test. 1.4 This practice may be used with a variety of stress corrosion test specimens, surface finishes, and methods of applying stress. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific precautionary statements, see Section 7.

信息:ICS:77.060 CCS:H25 发布:1998 实施:

ASTM C692-08 评估绝缘对奥氏体不锈钢外应力腐蚀开裂倾向影响的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2008-10-01 实施:

ASTM G35-1998 不锈钢及有关镍铬铁合金在连多硫酸中应力腐蚀断裂灵敏性的测定

简介:1.1 This practice describes procedures for preparing and conducting the polythionic acid test at room temperature, 22 to 25176C (72 to 77176F), to determine the relative susceptibility of stainless steels or other related materials (nickel-chromium-iron alloys) to intergranular stress corrosion cracking. 1.2 This practice can be used to evaluate stainless steels or other materials in the "as received" condition or after being subjected to high-temperature service, 482 to 815176C (900 to 1500176F), for prolonged periods of time. 1.3 This practice can be applied to wrought products, castings, and weld metal of stainless steels or other related materials to be used in environments containing sulfur or sulfides. Other materials capable of being sensitized can also be tested in accordance with this test. 1.4 This practice may be used with a variety of stress corrosion test specimens, surface finishes, and methods of applying stress. 1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific precautionary statements, see Section 7.

信息:ICS:77.040.10 (Mechanical testing of metals); 77.060 ( CCS:H25 发布:1998 实施:

ASTM C692-06 评估绝缘对奥氏体不锈钢外应力腐蚀开裂倾向影响的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2006-04-01 实施:

ASTM G35-1998(2015) 测定不锈钢和有关镍铬铁合金在连多硫酸中应力腐蚀断裂灵敏性的标准实施规程

简介: 4.1x00a0;This environment provides a way of evaluating the resistance of stainless steels and related alloys to intergranular stress corrosion cracking. Failure is accelerated by the presence of increasing amounts of intergranular precipitate. Results for the polythionic acid test have not been correlated exactly with those of intergranular corrosion tests. Also, this test may not be relevant to stress corrosion cracking in chlorides or caustic environments. 4.2x00a0;The polythionic acid environment may produce areas of shallow intergranular attack in addition to the more localized and deeper cracking mode of attack. Examination of failed specimens is necessary to confirm that failure occurred by cracking rather than mechanical failure of reduced sections. 1.1x00a0;This practice covers procedures for preparing and conducting the polythionic acid test at room temperature, 22 to 25x00b0;C (72 to 77x00b0;F), to determine the relative susceptibility of stainless steels or other related materials (nickel-chromiumiron alloys) to intergranular stress corrosion cracking. 1.2x00a0;This practice can be used to evaluate stainless steels or other materials in the x201c;as receivedx201d; condition or after being subjected to high-temperature service, 482 to 815x00b0;C (900 to 1500x00b0;F), for prolonged periods of time. 1.3x00a0;This practice can be applied to wrought products, castings, and weld metal of stainless steels or other related materials to be used in environments containing sulfur or sulfides. Other materials capable of being sensitized can also be tested in accordance with this test. 1.4x00a0;This practice may be used with a variety of stress corrosion test specimens, surface finishes, and methods of applying stress. 1.5x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific precautionary statements, see Section 7.

信息:ICS:77.040.10 CCS: 发布:1998 实施:

ASTM C692-2006 评定奥氏体不锈钢热绝缘材料对外部应力腐蚀开裂趋势影响的标准试验方法

简介:An inherent characteristic of some alloys of austenitic stainless steel is their tendency to crack at stress points when exposed to certain corrosive environments. The mechanisms of ESCC are complex and not completely understood but are apparently related to certain metallurgical properties. Chloride ions concentrated at a stress point will catalyze crack formation. It has been reported that other halide ions do not promote ESCC to the same degree as does chloride using the test technology of Test Method C 692 (drip test).3 Chlorides are common to many environments, so great care shall be taken to protect austenitic stainless steel from chloride contamination. Most thermal insulations will not, of themselves, cause stress corrosion cracking as shown by qualification tests. When exposed to elevated-temperature (boiling point range), environments containing chlorides, moisture, and oxygen, however, some insulation systems act as collecting media, transmigrating and concentrating chlorides on heated stainless steel surfaces. If moisture is not present, the chloride salts cannot migrate, and stress corrosion cracking because of chloride-contaminated insulation cannot take place. Insulation materials are available that are specially formulated to inhibit stress corrosion cracking in the presence of chlorides through modifications in basic composition or incorporation of certain chemical additives. The ability of the 28-day test to measure the corrosion potential of insulation materials is documented by Karnes,4 whose data appear to have been used for construction of the acceptability curve used in Specification C 795 and other specifications. The metal for all of the coupons used in this test method (C 692) shall be qualified (see Section 13) to ascertain that under conditions of the test, chloride ions will cause the metal to crack, and deionized water alone will not cause cracks.1.1 This test method covers two procedures for the laboratory evaluation of thermal insulation materials to determine whether they contribute to external stress corrosion cracking (ESCC) of austenitic stainless steel due to soluble chlorides within the insulation. This laboratory procedure is not intended to cover all of the possible field conditions that contribute to ESCC.1.2 While the 1977 edition of this test method (Dana test) is applicable only to wicking-type insulations, the procedures in this edition are intended to be applicable to all insulating materials, including cements, some of which disintegrate when tested in accordance with the 1977 edition. Wicking insulations are materials that wet through and through when partially (50 to 75 %) immersed in water for a short period of time (10 min or less).1.3 These procedures are intended primarily as a preproduction test for qualification of the basic chemical composition of a particular manufacturer''s product and are not intended to be routine tests for ongoing quality assurance or production lot compliance. Test Methods C 871, on the other hand, is used for confirmation of acceptable chemical properties of subsequent lots of insulation previously found acceptable by this test method.1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:77.060 (Corrosion of metals) CCS:Q25 发布:2006 实施:

ASTM G35-1998(2004) 不锈钢及有关镍铬铁合金在连多硫酸中应力腐蚀断裂灵敏性测定的标准实施规程

简介:This environment provides a way of evaluating the resistance of stainless steels and related alloys to intergranular stress corrosion cracking. Failure is accelerated by the presence of increasing amounts of intergranular precipitate. Results for the polythionic acid test have not been correlated exactly with those of intergranular corrosion tests. Also, this test may not be relevant to stress corrosion cracking in chlorides or caustic environments. The polythionic acid environment may produce areas of shallow intergranular attack in addition to the more localized and deeper cracking mode of attack. Examination of failed specimens is necessary to confirm that failure occurred by cracking rather than mechanical failure of reduced sections.1.1 This practice describes procedures for preparing and conducting the polythionic acid test at room temperature, 22 to 25176C (72 to 77176F), to determine the relative susceptibility of stainless steels or other related materials (nickel-chromium-iron alloys) to intergranular stress corrosion cracking. 1.2 This practice can be used to evaluate stainless steels or other materials in the "as received" condition or after being subjected to high-temperature service, 482 to 815176C (900 to 1500176F), for prolonged periods of time. 1.3 This practice can be applied to wrought products, castings, and weld metal of stainless steels or other related materials to be used in environments containing sulfur or sulfides. Other materials capable of being sensitized can also be tested in accordance with this test. 1.4 This practice may be used with a variety of stress corrosion test specimens, surface finishes, and methods of applying stress. 1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific precautionary statements, see Section 7.

信息:ICS:77.040.10 (Mechanical testing of metals); 77.060 ( CCS:H25 发布:1998 实施:

ASTM G123-00(2005) 沸腾酸化氯化钠溶液中不同镍含量不锈钢合金应力腐蚀开裂的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2005-10-01 实施:

ASTM G35-98 确定不锈钢和相关镍 - 铬 - 铁合金在多硫酸中应力腐蚀开裂的敏感性的标准实践

简介:

信息:ICS:77.040.10 CCS: 发布:1988-01-01 实施:

ASTM C692-05 评估绝缘对奥氏体不锈钢外应力腐蚀开裂倾向影响的标准试验方法

简介:

信息:ICS:77.060 CCS: 发布:2005-05-01 实施:

CNS 10171-1983 不锈钢之42%氯化镁应力腐蚀试验法

简介:本标准规定不锈钢在沸腾 42% 氯化镁溶液中试验应力腐蚀裂痕敏感性之试验方法。

信息:ICS:77.140 CCS: 发布:1983-04-13 实施:1983-04-13

ASTM C692-2005 评定奥氏体不锈钢热绝缘材料对外部应力腐蚀开裂趋势影响的标准试验方法

简介:1.1 This test method covers two procedures for the laboratory evaluation of thermal insulation materials that actively contribute to external stress corrosion cracking (ESCC) of austenitic stainless steel due to soluble chlorides within the insulation. This laboratory procedure is not intended to cover all of the possible field conditions that contribute to ESCC.1.2 While the 1977 edition of this test method (Dana test) is applicable only to wicking-type insulations, the procedures in this edition are intended to be applicable to all insulating materials, including cements, some of which disintegrate when tested in accordance with the 1977 edition. Wicking insulations are materials that wet through and through when partially (50 to 75 %) immersed in water for a short period of time (10 min or less).1.3 These procedures are intended primarily as a preproduction test for qualification of the basic chemical composition of a particular manufacturer''s product and are not intended to be routine tests for ongoing quality assurance or production lot compliance. Test Methods C 871, on the other hand, is used for confirmation of acceptable chemical properties of subsequent lots of insulation previously found acceptable by this test method.1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.1.5This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:77.060 (Corrosion of metals) CCS:Q25 发布:2005 实施:

HB 5260-1983 马氏体不锈钢拉伸应力腐蚀试验方法

简介:本标准适用于评定高强度马氏体不锈钢抗应力腐蚀的性能。用于评定合金的成分、热处理及加工工艺对应力腐蚀开裂敏感性。

信息:ICS: CCS:H40 发布:1982-10-01 实施:1984-01-01

ASTM G35-98(2004) 确定不锈钢和相关镍 - 铬 - 铁合金在多硫酸中应力腐蚀开裂的敏感性的标准实践

简介:

信息:ICS:77.040.10 CCS: 发布:2004-05-01 实施:

NF A05-305-1981 奥氏体不锈钢和镍铬铁奥氏体不锈合金.用四连硫酸钠应力试验测定晶间腐蚀

简介:

信息:ICS:77.060 CCS:H25 发布:1981-12-01 实施:1981-12-04

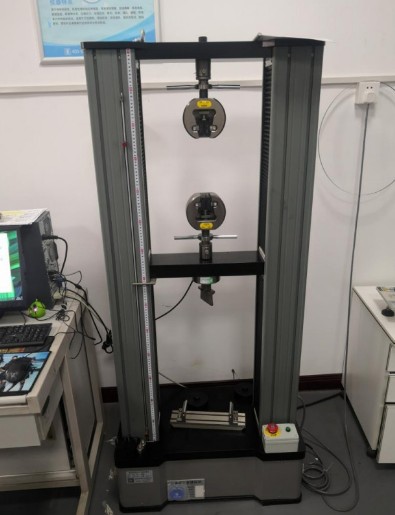

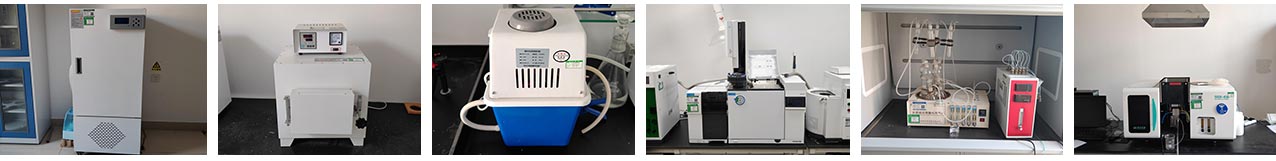

北检院部分仪器展示

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +