拉伸应变硬化指数检测标准相关信息

GB/T 5028-2008 金属材料.薄板和薄带.拉伸应变硬化指数(n值)的测定

简介:本标准规定了金属薄板和薄带拉伸应变硬化指数(n值)的测定方法。本方法仅适用于塑性变形范围内应力-应变曲线呈单调连续上升的部分(见7.4)。如果材料在加工硬化阶段的应力 -应变曲线呈锯齿状(如某些AlMg含金呈现出的Portevin-Le Chatelier 锯齿屈服效应),为使所给出的结果具有一定的重复性,应采用自动测量方法(对真实应力-真实塑性应变的对数进行线性回归,见 7.7)。

信息:ICS:77.040.10 CCS:H22 发布:2008-12-06 实施:2009-10-01

KS D 8512-2003(2018) 方法确定拉伸应变硬化指数期金属板带

简介:

信息:ICS:77.040.10 CCS: 发布:2003-10-08 实施:

GB/T 5028-1999 金属薄板和薄带拉伸应变硬化指数(n值)试验方法

简介: 本标准规定了金属薄板和薄带拉伸应变硬化指数(n值)试验方法的定义、符号、原理、试验设备、试样、试验程序、计算和试验报告。 本标准适用于厚度为0.1-3mm金属薄板和薄带拉伸应变硬化指数(n值)的测定。 本标准仅适用于均匀塑性变形范围内应力-应变曲线呈单调连续的部分。

信息:ICS:77.040.10 CCS:H22 发布:1999-11-01 实施:2000-08-01

SANS 10275-2003 金属材料.金属板和金属条.拉伸应变硬化指数的测定

简介:This International Standard specifies a method for determining the tensile strain hardening exponent n of flat products (sheet and strip) made of metallic materials. The method is valid only for that part of the stress- strain curve in the plastic range where the curve is continuous and monotonic

信息:ICS:77.040.10 CCS: 发布:2003 实施:

JIS Z2253-2020 金属材料. 钢板和带钢. 拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:2020-12-21 实施:

NF A03-659-2001 钢铁.薄钢板和钢板拉伸应变硬化指数n的测定方法

简介:

信息:ICS:77.040.10 CCS:H22 发布:2001-11-01 实施:2001-11-20

DIN EN ISO 10275-2020 金属材料. 薄板和带. 拉伸应变硬化指数的测定(ISO 10275-2020); 德文版 EN ISO 10275-2020

简介:This international standard specifies a method for determining the tensile strain hardening exponent n of flat products (sheet and strip) made of metallic materials.The method is valid only for that part of the stress-strain curve in the plastic range where the curve is continuou

信息:ICS:77.040.10 CCS: 发布:2020-12-01 实施:

ASTM E646-00 金属板材拉伸应变硬化指数的标准试验方法( n -Values)

简介:

信息:ICS:77.140.50 CCS: 发布:2000-05-10 实施:

ISO 10275:2020 金属材料 - 板材和带材 - 拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:2020-08-19 实施:

ASTM E646-2000 金属薄板材料拉伸应变硬化指数(N-值)的标准试验方法

简介:This test method is useful for estimating the strain at the onset of necking in a uniaxial tension test (1). Practically, it provides an empirical parameter for appraising the relative stretch formability of similar metallic systems. The strain-hardening exponent is also a measure of the increase in strength of a material due to plastic deformation. The strain-hardening exponent may be determined over the entire plastic stress-strain curve or any portion(s) of the stress-strain curve specified in a product specification. Note 38212;The strain interval 10x2013;20% is commonly utilized for determining the n-value of formable low carbon steel products. This test method is not intended to apply to any portion of the true-stress versus true-strain curve that exhibits discontinuous behavior; however, the method may be applied by curve-smoothing techniques as agreed upon. Note 48212;For example, those portions of the stress-strain curves for mild steel or aluminum alloys which exhibit yield-point elongation or Luuml;ders bands may be characterized as behaving discontinuously. Note 58212;Caution should be observed in the use of curve-smoothing techniques as they may affect the n-value. This test method is suitable for determining the tensile stress-strain response of metallic sheet materials in the plastic region prior to the onset of necking. The n-value may vary with the displacement rate or strain rate used, depending on the metal and test temperature.1.1 This test method covers the determination of a strain-hardening exponent by tension testing of metallic sheet materials for which plastic-flow behavior obeys the power curve given in the Introduction. 1.2 This test method is for metallic sheet materials with thicknesses of at least 0.005 in. (0.13 mm) but not greater than 0.25 in. (6.4 mm). 1.3 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents shown may be approximate. 1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:77.140.50 (Flat steel products and semi-products) CCS:H23 发布:2000 实施:

ISO 10275-2020 金属材料 - 板材和带材 - 拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:2020-08-19 实施:

STAS SR ISO 10275-1996 金属材料.薄膜和膜片.拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:1996-3-1 实施:

ASTM E646-16 金属薄板材料拉伸应变硬化指数(n值)的标准试验方法

简介:

信息:ICS:77.140.50 CCS: 发布:2016-02-01 实施:

ISO 10275:1993 金属材料.薄板和带材.拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:1993-02-04 实施:

ASTM E646-2016 金属薄板材拉伸应变硬化指数 (n值) 的标准试验方法

简介: 5.1x00a0;This test method is useful for estimating the strain at the onset of necking in a uniaxial tension test (1). Practically, it provides an empirical parameter for appraising the relative stretch formability of similar metallic systems. The strain-hardening exponent is also a measure of the increase in strength of a material due to plastic deformation. 5.2x00a0;The strain-hardening exponent may be determined over the entire plastic stress-strain curve or any portion(s) of the stress-strain curve specified in a product specification. Note 4:x00a0;The engineering strain interval 10x2013;20% is commonly used for determining the strain-hardening exponent, n, of formable low-carbon steel products 5.3x00a0;This test method is not intended to apply to any portion of the true stress versus true strain curve that exhibits discontinuous behavior; however, the method may be applied by curve-smoothing techniques as agreed upon. Note 5:x00a0;For example, those portions of the stress-strain curves for mild steel, aluminum, or other alloys that exhibit yield point and Lx00fc;ders band elongation, twinning, or Portevinx2013;Le Chatelier effect (PLC) may be characterized as behaving discontinuously. Note 6:x00a0;Caution should be observed in the use of curve-smoothing techniques as they may affect the n-value. 5.4x00a0;This test method is suitable for determining the tensile stress-strain response of metallic sheet materials in the plastic region prior to the onset of necking. 5.5x00a0;The n-value may vary with the displacement rate or strain rate used, depending on the metal and test temperature. 1.1x00a0;This test method covers the determination of a strain-hardening exponent by tension testing of metallic sheet materials for which plastic-flow behavior obeys the power curve given in the Introduction. Note 1:x00a0;A single power curve may not be a satisfactory fit to the entire stress-strain curve between yield and necking. If such is the case, more than one value of the strain-hardening exponent may be obtained (2) by agreement using this test method. 1.2x00a0;This test method is specifically for metallic sheet materials with thicknesses of at least 0.005 in. (0.13 mm) but not greater than 0......

信息:ICS:77.140.50 CCS: 发布:2016 实施:

ISO 10275-1993 金属材料 薄板和钢带 拉伸应变硬化指数的测定

简介:The principle of the test method specified is subjecting a test piece to uniaxial tensile strain at a prescribed constant rate within the region of uniform plastic strain. It is valid only for that part of the stress-strain curve in the plastic range where the curve is continuous and monotonic. The tensile strain hardening exponent is calculated either by considering a portion of the stress-strain curve in the plastic strain region, or by considering the whole of the uniform plastic strain region.

信息:ICS:77.040.10 CCS:H22 发布:1993-02 实施:

ASTM E646-15 金属薄板材料拉伸应变硬化指数(n值)的标准试验方法

简介:

信息:ICS:77.140.50 CCS: 发布:2015-11-15 实施:

ASTM E646-2015 金属薄板材拉伸应变硬化指数 (n值) 的标准试验方法

简介: 5.1x00a0;This test method is useful for estimating the strain at the onset of necking in a uniaxial tension test (1). Practically, it provides an empirical parameter for appraising the relative stretch formability of similar metallic systems. The strain-hardening exponent is also a measure of the increase in strength of a material due to plastic deformation. 5.2x00a0;The strain-hardening exponent may be determined over the entire plastic stress-strain curve or any portion(s) of the stress-strain curve specified in a product specification. Note 4:x00a0;The engineering strain interval 10x2013;20% is commonly used for determining the strain-hardening exponent, n, of formable low-carbon steel products 5.3x00a0;This test method is not intended to apply to any portion of the true -stress versus true -strain curve that exhibits discontinuous behavior; however, the method may be applied by curve-smoothing techniques as agreed upon. Note 5:x00a0;For example, those portions of the stress-strain curves for mild steel, aluminum, or other alloys that exhibit yield point and Lx00fc;ders band elongation, twinning, or Portevinx2013;Le Chatelier effect (PLC) may be characterized as behaving discontinuously. Note 6:x00a0;Caution should be observed in the use of curve-smoothing techniques as they may affect the n-value. 5.4x00a0;This test method is suitable for determining the tensile stress-strain response of metallic sheet materials in the plastic region prior to the onset of necking. 5.5x00a0;The n-value may vary with the displacement rate or strain rate used, depending on the metal and test temperature. 1.1x00a0;This test method covers the determination of a strain-hardening exponent by tension testing of metallic sheet materials for which plastic-flow behavior obeys the power curve given in the Introduction. Note 1:x00a0;A single power curve may not be a satisfactory fit to the entire stress-strain curve between yield and necking. If such is the case, more than one value of the strain-hardening exponent may be obtained (2) by agreement using this test method. 1.2x00a0;This test method is specifically for metallic sheet materials with thicknesses of at least 0.005 in. (0.13 mm) but not greater than......

信息:ICS:77.140.50 CCS: 发布:2015 实施:

NF A03-659-2014 金属材料. 薄板材和带材. 拉伸应变硬化指数的测定

简介:La présente Norme internationale spécifie une méthode pour la détermination du coefficient d'écrouissage en traction, n, des produits plats (tôles et bandes) en matériaux métalliques.

信息:ICS:77.040.10 CCS:H22 发布:2014-08-23 实施:2014-08-23

EN ISO 10275-2014 金属材料.薄板和薄带拉伸应变硬化指数(ISO 10275:2007)

简介:Diese Internationale Norm legt ein Verfahren zur Bestimmung des Verfestigungsexponenten n im Zugversuch von Flacherzeugnissen (Band und Blech) aus metallischen Werkstoffen fest. Das Verfahren ist nur anwendbar fur den plastischen Bereich der Spannung/Dehnung-Kurve, in dem die Kurve kontinuierlich und monoton verlauft (siehe 7.4). Bei Werkstoffen mit gezackter Spannung/Dehnung-Kurve im Verfestigungsbereich (Werkstoffe mit Portevin-Le Chatelier Effekt, z. B. AlMg-Legierungen) sollte die automatisierte Bestimmung (lineare Regression der logarithmierten wahren Spannung uber die logarithmierte wahre plastische Dehnung, siehe 7.7) angewendet werden, um reproduzierbare Ergebnisse zu erhalten.

信息:ICS:77.040.10 CCS:H22 发布:2014-06 实施:

JIS Z2253-2011 金属材料.金属片和带材.拉伸应变硬化指数测定

简介:

信息:ICS:77.040.10 CCS:H22 发布:2011-02-21 实施:

KS B ISO 10275-2009(2022) 金属材料薄板和带材拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:2009-12-30 实施:

KS B ISO 10275-2009(2017) 金属材料 - 薄板和薄带 - 拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:2009-12-30 实施:

ASTM E646-07e1 拉伸应变硬化指数&40的标准试验方法n-值和41;金属薄板材料

简介:

信息:ICS:77.140.50 CCS: 发布:2007-12-01 实施:

ASTM E646-07 金属薄板材料拉伸应变硬化指数(n-值)的标准试验方法

简介:

信息:ICS:77.140.50 CCS: 发布:2007-12-01 实施:

ISO 10275:2007 金属材料——薄板和带材——拉伸应变硬化指数的测定

简介:

信息:ICS:77.040.10 CCS: 发布:2007-05-30 实施:

ASTM E646-2007e1 金属薄板材拉伸应变硬化指数40;n值41的标准试验方法

简介: 5.1x00a0;This test method is useful for estimating the strain at the onset of necking in a uniaxial tension test (1). Practically, it provides an empirical parameter for appraising the relative stretch formability of similar metallic systems. The strain-hardening exponent is also a measure of the increase in strength of a material due to plastic deformation. 5.2x00a0;The strain-hardening exponent may be determined over the entire plastic stress-strain curve or any portion(s) of the stress-strain curve specified in a product specification.Note 3x2014;The strain interval 10x2013;20% is commonly utilized for determining the n-value of formable low carbon steel products. 5.3x00a0;This test method is not intended to apply to any portion of the true-stress versus true-strain curve that exhibits discontinuous behavior; however, the method may be applied by curve-smoothing techniques as agreed upon.Note 4x2014;For example, those portions of the stress-strain curves for mild steel or aluminum alloys which exhibit yield-point elongation or Lx00fc;ders bands may be characterized as behaving discontinuously.Note 5x2014;Caution should be observed in the use of curve-smoothing techniques as they may affect the n-value. 5.4x00a0;This test method is suitable for determining the tensile stress-strain response of metallic sheet materials in the plastic region prior to the onset of necking. 5.5x00a0;The n-value may vary with the displacement rate or strain rate used, depending on the metal and test temperature. 1.1x00a0;This test method covers the determination of a strain-hardening exponent by tension testing of metallic sheet materials for which plastic-flow behavior obeys the power curve given in the Introduction. Note 1x2014;A single power curve may not fit the entire stress-strain curve between yield and necking. If such is the case, more than one value of the strain-hardening exponent can be obtained (2). 1.2x00a0;This test method is for metallic sheet materials with thicknesses of at least 0.005 in. (0.13 mm) but not greater than 0.25 in. (6.4 mm). 1.3x00a0;The values stated in inch-pound units are to be regarded as the standard. The SI equivalents shown may be approximate. 1.4x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:77.140.50 (Flat steel products and semi-products) CCS:H46 发布:2007 实施:

ASTM E646-2007 金属薄板材拉伸应变硬化指数(n值)的标准试验方法

简介:This test method is useful for estimating the strain at the onset of necking in a uniaxial tension test (1). Practically, it provides an empirical parameter for appraising the relative stretch formability of similar metallic systems. The strain-hardening exponent is also a measure of the increase in strength of a material due to plastic deformation. The strain-hardening exponent may be determined over the entire plastic stress-strain curve or any portion(s) of the stress-strain curve specified in a product specification. Note 38212;The strain interval 10x2013;20% is commonly utilized for determining the n-value of formable low carbon steel products. This test method is not intended to apply to any portion of the true-stress versus true-strain curve that exhibits discontinuous behavior; however, the method may be applied by curve-smoothing techniques as agreed upon. Note 48212;For example, those portions of the stress-strain curves for mild steel or aluminum alloys which exhibit yield-point elongation or Luuml;ders bands may be characterized as behaving discontinuously. Note 58212;Caution should be observed in the use of curve-smoothing techniques as they may affect the n-value. This test method is suitable for determining the tensile stress-strain response of metallic sheet materials in the plastic region prior to the onset of necking. The n-value may vary with the displacement rate or strain rate used, depending on the metal and test temperature.1.1 This test method covers the determination of a strain-hardening exponent by tension testing of metallic sheet materials for which plastic-flow behavior obeys the power curve given in the Introduction. Note 18212;A single power curve may not fit the entire stress-strain curve between yield and necking. If such is the case, more than one value of the strain-hardening exponent can be obtained (2). 1.2 This test method is for metallic sheet materials with thicknesses of at least 0.005 in. (0.13 mm) but not greater than 0.25 in. (6.4 mm). 1.3 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents shown may be approximate. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:77.140.50 (Flat steel products and semi-products) CCS:H22 发布:2007 实施:

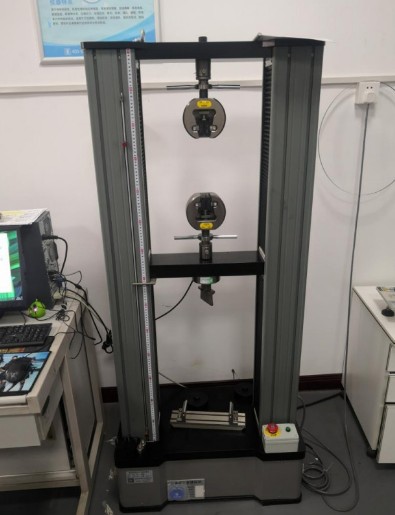

北检院部分仪器展示

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +