氢脆检测标准相关信息

GB/T 15970.11-2022 金属和合金的腐蚀 应力腐蚀试验 第11部分:金属和合金氢脆和氢致开裂试验指南

简介:

信息:ICS:77.060 CCS:H25 发布:2022-12-30 实施:2023-07-01

ASTM B577-19 铜中氧化亚铜(氢脆敏感性)检测的标准试验方法

简介:

信息:ICS:77.120.30 CCS: 发布:2019-04-01 实施:

ISO 16573:2015 钢 - 高强度钢的耐氢脆性评价方法

简介:

信息:ICS:77.040.99 CCS: 发布:2015-03-25 实施:

GB/Z 41117-2021 紧固件 钢制紧固件氢脆基本原理

简介:

信息:ICS:21.060.01 CCS:J13 发布:2021-12-31 实施:2022-07-01

ASTM B849-02(2019) 降低氢脆风险的钢铁预处理的标准规范

简介:

信息:ICS:77.080.01 CCS: 发布:2019-04-01 实施:

ASTM B850-98(2015) 钢的后处理标准指南 用于降低氢脆风险

简介:

信息:ICS:77.080.01 CCS: 发布:2015-01-01 实施:

GB/T 34542.3-2018 氢气储存输送系统 第3部分:金属材料氢脆敏感度试验方法

简介:

信息:ICS:27.180 CCS:F19 发布:2018-05-14 00:00:00.0 实施:2018-12-01 00:00:00.0

ISO/TR 20491-2019 紧固件.钢紧固件氢脆的基本原理

简介:

信息:ICS:21.060.01 CCS: 发布:2019-02-19 实施:

ASTM F2078-2015 有关氢脆化试验的标准术语

简介: 3.1x00a0;The terms used in describing hydrogen embrittlement have precise definitions. The terminology and its proper usage must be completely understood to communicate and transfer information adequately within the field. 3.2x00a0;The terms defined in other terminology standards, are respectively identified in parentheses following the definition. 1.1x00a0;This terminology covers the principal terms, abbreviations, and symbols relating to mechanical methods for hydrogen embrittlement testing, which are present in more than one of the standards under the jurisdiction of ASTM Committee F07 on Aerospace and Aircraft. These definitions are published to encourage uniformity of terminology in product specifications.

信息:ICS:01.040.19 CCS: 发布:2015 实施:

GB/T 19349-2012 金属和其它无机覆盖层 为减少氢脆危险的钢铁预处理

简介:本标准规定了高强度钢消除应力热处理的要求,以便降低随后进行的预处理、电镀、化学镀、化学转化及磷化过程中的氢脆敏感性或敏感性程度。本标准适用于在190℃~230℃或更高的温度下对其热处理而不导致其性能降低的钢(参见6.2)。本标准规定的热处理工序对减少抗拉强度等于或高于1 000 MPa并在热处理后经机械加工、磨削、冷成型或冷矫直处理的钢的氢脆敏感性是有效的。该热处理工序用在可能出现零件渗氢的任一工序之前,就如同清洗工序用于电镀、化学镀和其他化学覆盖层操作之前一样。本标准不适用于紧固件。

信息:ICS:25.220.40 CCS:A29 发布:2012-12-31 实施:2013-10-01

ASTM F1624-12(2018) 用递增阶跃加载技术测量钢中氢脆阈值的标准试验方法

简介:

信息:ICS:77.040.10 CCS: 发布:2018-11-01 实施:

ASTM F1940-07a(2014) 用于防止镀层或涂层紧固件中的氢脆化的过程控制验证的标准测试方法

简介:

信息:ICS:21.060.01 CCS: 发布:2014-08-01 实施:

GB/T 19350-2012 金属和其它无机覆盖层 为减少氢脆危险的涂覆后钢铁的处理

简介:本标准规定了减少表面精饰过程中可能出现的氢脆敏感性或敏感性程度的方法、本标准规定的钢铁热处理工序能有效地减少氢脆敏感性、这些热处理工序在表面精饰之后,但在任何二次转化膜工序之前、在加工过程之后但在表面精饰之前使用的消除应力热处理工序在ISO 9587中作了规定、本标准不适用于紧固件、

信息:ICS:25.220.40 CCS:A29 发布:2012-12-31 实施:2013-10-01

ASTM F326-17 用电镀方法测量氢脆的电子测量的标准试验方法

简介:

信息:ICS:25.220.40 CCS: 发布:2017-12-01 实施:

ASTM F519-13 电镀/镀层工艺和服务环境机械氢脆评估的标准试验方法

简介:

信息:ICS:25.220.40 CCS: 发布:2013-12-01 实施:

GB/T 26107-2010 金属与其他无机覆盖层 镀覆和未镀覆金属的外螺纹和螺杆的残余氢脆试验 斜楔法

简介:重要提示:实施本标准要特别审慎。氢脆件或杆的顶端会陡然破坏,而形成飞起抛射物,可能造成失明或其他严重伤害。这种危险可能在试验进行长达200h之后发生,应提供遮挡或其他装置,以避免此类伤害。本标准规定了以统计学为依据确定的以下氢脆或氢破坏存在几率的方法a)成批滚镀、化学镀、磷化或化学处理的螺纹件;b)挂镀螺纹件或螺杆。本标准适用于抗拉强度≥1000MPa(相应硬度:300HV, 303HB或31HRC)的钢制螺纹件或螺杆和表面硬化螺纹件或螺杆。不适用于紧固件扣件。本方法在去除氢脆热处理之后实施。本方法还可用于评价处理溶液、使用条件和技术之间的差异。本试验方法有两个主要作用:a)采用统计抽样方法时,可判断批量接受或报废;b)可用作控制测试,以确定有效的各种处理步骤,其中包括为减少螺纹件和螺杆中氢浓度的前、后热处理。虽然本试验方法能确定制件的氢脆程度,但它并不能确保完全无氢脆。本标准并不能免除镀覆人员、工艺人员或生产者实施和监测适当的工艺过程控制。

信息:ICS:25.220-70 CCS:A29 发布:2011-01-10 实施:2011-10-01

ASTM F519-17a 电镀/镀层工艺和服务环境机械氢脆评估的标准试验方法

简介:

信息:ICS:25.220.40 CCS: 发布:2017-12-01 实施:

ASTM F2660-13 用于A490结构螺栓相对于环境氢脆的合格涂层的标准测试方法

简介:

信息:ICS:21.060.10 CCS: 发布:2013-11-01 实施:

GB/T 24185-2009 逐级加力法测定钢中氢脆临界值试验方法

简介:本标准规定了一种用逐级加力法测定钢中氢脆临界应力值和临界应力强度值的符号与说明、原理、试验设备、试样、试验程序和试验报告。本标准适用于定量评估钢的氢脆敏感性,或冶炼、热加工、表面处理等加工过程产生的钢内残余氢以及环境外部氢对钢性能的影响。

信息:ICS:77.040.10 CCS:H22 发布:2009-06-25 实施:2010-04-01

BS EN ISO 11114-4-2017 运输储气瓶.储气瓶和阀门材料与盛装气体的兼容性.选择耐氢脆钢的试验方法

简介:

信息:ICS:23.020.35 CCS:J74;E98 发布:2017-06-20 实施:2017-06-20

BS ISO 7539-11-2013 金属与合金的腐蚀. 应力腐蚀开裂. 金属与合金耐氢脆化和氢助开裂的试验指南

简介:

信息:ICS:77.060 CCS:A29 发布:2013-07-31 实施:2013-07-31

GB/T 23606-2009 铜氢脆检验方法

简介:本标准规定了脱氧铜和无氧铜氢脆试验的方法。本标准适用于脱氧铜和无氧铜氢脆的检验。

信息:ICS:77.040.99 CCS:H13 发布:2009-04-15 实施:2010-02-01

KS B ISO 15330-2017(2022) 紧固件-检测氢脆的预加载试验-平行支承面法

简介:

信息:ICS:21.060.01 CCS: 发布:2017-04-28 实施:

ASTM B849-02(2013) 降低氢脆风险的钢铁预处理的标准规范

简介:

信息:ICS:77.080.01 CCS: 发布:2013-05-01 实施:

GB/T 19350-2003 金属和其他无机覆盖层为减少氢脆危险的涂覆后钢铁的处理

简介:本标准规定了减少表面精饰过程中可能出现的氢脆敏感性或敏感性程度的方法。 . 本标准规定的热处理工序能有效地减少氢脆敏感性。这些热处理工序在表面精饰之后,但在任何二次转化膜工序之前进行。 在加工过程之后但在表面精饰之前使用的消除应力热处理工序在GB/T l9349中作了规定。 本标准不适用于紧固件。 注:热处理不保证完全消除氢瞻的有害影响。

信息:ICS:25.220.20 CCS:A29 发布:2003-10-29 实施:2004-05-01

EN ISO 11114-4-2017 气瓶的气瓶和阀门材料与气体含量第4部分兼容性:选择抗氢脆钢试验方法(ISO 11114-4:2017)

简介:

信息:ICS:23.020.35 CCS:J16 发布:2017-04 实施:

ISO 7539-11:2013 金属和合金的腐蚀——应力腐蚀裂纹第11部分:金属和合金抗氢脆和氢辅助裂纹的试验指南

简介:

信息:ICS:77.060 CCS: 发布:2013-04-09 实施:

GB/T 19349-2003 金属和其他无机覆盖层为减少氢脆危险的钢铁预处理

简介:本标准规定了消除高强度钢应力的要求,以便降低随后进行的预处理、电镀、化学镀、化学转化及磷化过程中的氢脆敏感性或敏感性程度。本标准适用于在190℃~230℃或更高的温度下对其热处理而不导致其性能降低的钢(参见6.2)。 本标准规定的热处理工序对减少抗拉强度等于或高于1 000 Mpa并在热处理后经机械加工、磨削、冷成型或冷矫直处理的钢的氢脆敏感性是有效的。该热处理工序用在可能出现零件渗氢的任一工序之前,就如同清洗工序用于电镀、化学镀和其他化学覆盖层操作之前一样。 本标准不适用于紧固件。

信息:ICS:25.220.20 CCS:A29 发布:2003-10-29 实施:2004-05-01

ISO 11114-4-2017 移动气瓶.气瓶和瓶阀材料与盛装气体的相容性.第4部分:选择抗氢脆钢的试验方法

简介:

信息:ICS:23.020.35 CCS:J74 发布:2017-04 实施:

ISO 7539-11-2013 金属和合金的腐蚀.应力腐蚀试验.第11部分:金属和合金耐氢脆性和氢辅助破裂性测试用指南

简介:

信息:ICS:77.060 CCS:H25 发布:2013-04 实施:

GB/T 3098.17-2000 紧固件机械性能 检查氢脆用预载荷试验 平行支承面法

简介: 本标准规定了检查紧固件在室温条件下发生氢脆的预载荷试验方法. 本标准适用于: a)螺栓,螺钉和螺柱; b)自挤螺钉; c)自攻螺钉; d)自钻自攻螺钉; e)螺母 f)垫圈 这些紧固件均由钢制成,并承受拉应力。 本实验的温度范围为10-35度 本实验仅适用于过程控制,可在任何制造工艺后进行,但并不作为验收试验的项目。本实验能评估工艺状态和技术状态的差异和变化,确定不同工艺的不同效果,包括镀前处理和为减少紧固件中的游离氢而进行的镀后处理(烘烤)。 制造人员和工艺人员不能因为本实验而解除采用和监控过程控制的责任。

信息:ICS:21.060.01 CCS:J13 发布:2000-09-26 实施:2001-02-01

ISO 11114-4-2017 移动气瓶.气瓶和瓶阀材料与盛装气体的相容性.第4部分:选择抗氢脆钢的试验方法

简介:

信息:ICS:23.020.35 CCS:J74 发布:2017-04 实施:

ASTM F2660-2013 涉及环境氢脆的A490结构螺栓用涂层合格性的标准试验方法

简介: 4.1x00a0;This test method describes the testing procedure that shall be used to qualify a coating system that is under consideration for use on ASTM A490 high strength structural bolts made of any steel composition permitted by the A490 specification. The test method measures the susceptibility of coated specimen bolts to the influence of an externally applied potential (see 7.2.3.3) by testing for the threshold of embrittlement in a salt solution environment. 1.1x00a0;This test method defines the procedures and tests to evaluate the effect of a coating system on the susceptibility to environmental hydrogen embrittlement (EHE) of an ASTM A490 high strength structural bolt. 1.2x00a0;This test method shall qualify a coating system for use with any size of A490 bolts (that is, 1/2x00a0;to 1-1/2x00a0;in.) high strength structural bolts, relative to EHE. 1.3x00a0;The characteristic to be evaluated by this test method is the susceptibility to EHE caused by hydrogen generated from corrosion protection of the steel bolt by sacrificial galvanic corrosion of the coating. Testing shall be performed on coated, specimen ASTM A490 bolts manufactured to the maximum susceptible tensile strength values (see Table 1) of the bolt (see Section 5 Specimen Bolt Requirements). The internal hydrogen embrittlement (IHE) susceptibility will also be inherently evaluated when the EHE is tested through this test method. There is no need for a separate IHE susceptibility test. 1.4x00a0;The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard. 1.5x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:21.060.10 CCS:J13 发布:2013 实施:

GB/T 13322-1991 金属覆盖层 低氢脆镉钛电镀层

简介: 本标准规定了高强度钢零件低氢脆镀镉钛的质量检验要求、检验方法和镀前检验要求。 本标准适用于高强度钢零件低氢脆镀镉钛的镀前和镀后质量检验。

信息:ICS:25.220.40 CCS:A29 发布:1991-12-13 实施:1992-10-01

ISO 11114-4:2017 可移动气瓶 - 气瓶和阀门材料与气体含量的兼容性 - 第4部分:选择耐氢脆性钢的试验方法

简介:

信息:ICS: CCS: 发布:2017-03-30 实施:

ASTM F519-2013 评定电镀/涂覆工艺机械氢脆和工作环境的标准试验方法

简介: 5.1x00a0;Plating/coating Processesx2014;This test method provides a means by which to detect possible hydrogen embrittlement of steel parts during manufacture by verifying strict controls during production operations such as surface preparation, pretreatments, and plating/coating. It is also intended to be used as a qualification test for new plating/coating processes and as a periodic inspection audit for the control of a plating/coating process. 5.2x00a0;Service Environmentx2014;This test method provides a means by which to detect possible hydrogen embrittlement of steel parts (plated/coated or bare) due to contact with chemicals during manufacturing, overhaul and service life. The details of testing in a service environment are found in Annex A5. 1.1x00a0;This test method describes mechanical test methods and defines acceptance criteria for coating and plating processes that can cause hydrogen embrittlement in steels. Subsequent exposure to chemicals encountered in service environments, such as fluids, cleaning treatments or maintenance chemicals that come in contact with the plated/coated or bare surface of the steel, can also be evaluated. 1.2x00a0;This test method is not intended to measure the relative susceptibility of different steels. The relative susceptibility of different materials to hydrogen embrittlement may be determined in accordance with Test Method F1459 and Test Method F1624. 1.3x00a0;This test method specifies the use of air melted AISI E4340 steel per SAE AMS-S-5000 (formerly MIL-S-5000) heat treated to 260 to 280 ksi (pounds per square inch x00d7;1000) as the baseline. This combination of alloy and heat treat level has been used for many years and a large database has been accumulated in the aerospace industry on its specific response to exposure to a wide variety of maintenance chemicals, or electroplated coatings, or both. Components with ultimate strengths higher than 260 to 280 ksi may not be represented by the baseline. In such cases, the cognizant engineering authority shall determine the need for manufacturing specimens from the specific material and heat treat condition of the component. Deviations from the baseline shall be reported as required by 12.1.2. The sensitivity to hydrogen embrittlement shall be demonstrated for each lot of specimens as specified in 9.5. 1.4x00a0;Test procedures and acceptance requirements are specified for seven specimens of different sizes, geometries, and loading configurations. 1.5x00a0;Pass/Fail Requirementsx2014;For plating/coating processes, specimens must meet or exceed 200 h using a sustained load test (SLT) at the levels shown in Table 3.TABLE 1 Lot Acceptance Criteria for Notched Specimens

信息:ICS:25.220.40 (Metallic coatings) CCS: 发布:2013 实施:

ASTM F326-23 电镀镉过程中氢脆的电子测量的标准试验方法

简介:

信息:ICS:25.220.40 CCS: 发布:2023-01-01 实施:

ASTM F519-17 电镀/镀层工艺和服务环境机械氢脆评估的标准试验方法

简介:

信息:ICS:25.220.40 CCS: 发布:2017-03-01 实施:

ASTM F2660-2013 涉及环境氢脆的A490结构螺栓用涂层合格性的标准试验方法

简介: 4.1x00a0;This test method describes the testing procedure that shall be used to qualify a coating system that is under consideration for use on ASTM A490 high strength structural bolts made of any steel composition permitted by the A490 specification. The test method measures the susceptibility of coated specimen bolts to the influence of an externally applied potential (see 7.2.3.3) by testing for the threshold of embrittlement in a salt solution environment. 1.1x00a0;This test method defines the procedures and tests to evaluate the effect of a coating system on the susceptibility to environmental hydrogen embrittlement (EHE) of an ASTM A490 high strength structural bolt. 1.2x00a0;This test method shall qualify a coating system for use with any size of A490 bolts (that is, 1/2x00a0;to 1-1/2x00a0;in.) high strength structural bolts, relative to EHE. 1.3x00a0;The characteristic to be evaluated by this test method is the susceptibility to EHE caused by hydrogen generated from corrosion protection of the steel bolt by sacrificial galvanic corrosion of the coating. Testing shall be performed on coated, specimen ASTM A490 bolts manufactured to the maximum susceptible tensile strength values (see Table 1) of the bolt (see Section 5 Specimen Bolt Requirements). The internal hydrogen embrittlement (IHE) susceptibility will also be inherently evaluated when the EHE is tested through this test method. There is no need for a separate IHE susceptibility test. 1.4x00a0;The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard. 1.5x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:21.060.10 (Bolts, screws, studs) CCS:J13 发布:2013 实施:

ASTM F2078-22 与氢脆试验有关的标准术语

简介:

信息:ICS:01.040.19 CCS: 发布:2022-05-01 实施:

KS B 1105-2017(2022) 高强度螺栓氢脆敏感性的SSRT测量方法

简介:

信息:ICS:21.060.10 CCS: 发布:2017-02-17 实施:

ASTM F519-12a 电镀/镀层工艺和服务环境机械氢脆评估的标准试验方法

简介:

信息:ICS:25.220.40 CCS: 发布:2012-11-15 实施:

ASTM B850-98(2022) 降低氢脆风险用钢的后涂层处理的标准指南

简介:

信息:ICS:77.080.01 CCS: 发布:2022-05-01 实施:

ASTM B577-16 铜中氧化亚铜(氢脆敏感性)检测的标准试验方法

简介:

信息:ICS:77.120.30 CCS: 发布:2016-04-01 实施:

ASTM F326-96(2012) 用电镀方法测量氢脆的电子测量的标准试验方法

简介:

信息:ICS:25.220.40 CCS: 发布:2012-11-01 实施:

ISO 16573-2-2022 钢.高强度钢抗氢脆性评估的测量方法.第2部分:慢应变率试验

简介:

信息:ICS:77.040.99 CCS: 发布:2022-02-28 实施:

ASTM B577-2016 测定铜中氧化亚铜 (氢脆敏感性) 的标准试验方法

简介: 5.1x00a0;These test methods determine whether copper products will be resistant to embrittlement when exposed to elevated temperatures in a reducing atmosphere. 5.1.1x00a0;It is assumed that all who use these test methods will be trained personnel capable of performing these procedures skillfully and safely. It is expected that work will be performed in a properly equipped facility. 1.1x00a0;These test methods describe procedures for determining the presence of cuprous oxide (Cu2O) in products made from deoxidized and oxygen-free copper. 1.2x00a0;The test methods appear in the following order: x00a0; Sections x00a0; x00a0; Microscopical Examination without Thermal Treatment 9 x2013; 11 Microscopical Examination after Thermal Treatment 13 x2013; 15 Closed Bend Test after Thermal Treatment 17 x2013; 19 Reverse Bend Test after Thermal Treatment 21 x2013; 23 1.3x00a0;Unitsx2014;The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.4x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this stand......

信息:ICS:4200 CCS: 发布:2016 实施:

SAE AMS 2451/9B-2012 低氢脆性锌-镍电镀刷

简介:This specification covers the engineering requirements and processes for brush plating of zinc-nickel by electrodeposition. This process has been used typically to improve corrosion resistance of steel parts operating under 500 °F (260 °C) asplated or under 250 °F (121 °C) when chromate treated, to repair zinc-nickel deposits and to repair damaged or worn parts, but usage is not limited to such applications.

信息:ICS:49.040 CCS:V18 发布:2012-09-20 实施:

ISO 16573-1-2020 钢 - 高强度钢的耐氢脆性评价方法

简介:

信息:ICS:77.040.99 CCS: 发布:2020-08-14 实施:

ASTM F2078-15 关于氢脆性测试的标准术语

简介:

信息:ICS:01.040.19 CCS: 发布:2015-11-01 实施:

ASTM F2660-12 A490结构螺栓上使用的与氢脆有关的涂层评定的标准试验方法

简介:

信息:ICS:21.060.10 CCS: 发布:2012-09-01 实施:

ASTM F2660-20 F3125 A490级结构螺栓上使用的与环境氢脆有关的涂层评定的标准试验方法

简介:

信息:ICS:21.060.10 CCS: 发布:2020-04-01 实施:

ASTM A1032-15 预应力混凝土管用硬拉钢丝耐氢脆性的标准试验方法

简介:

信息:ICS:77.140.15 CCS: 发布:2015-05-01 实施:

ASTM F1624-12 用递增阶跃加载技术测量钢中氢脆阈值的标准试验方法

简介:

信息:ICS:77.040.10 CCS: 发布:2012-08-01 实施:

ASTM A1032-15(2019) 预应力混凝土管用硬拉钢丝耐氢脆性的标准试验方法

简介:

信息:ICS:77.140.15 CCS: 发布:2019-11-01 实施:

BS ISO 16573-2015 钢材. 估高强度钢材抗氢脆性的测量方法

简介:

信息:ICS:77.040.99 CCS:H11 发布:2015-04-30 实施:2015-04-30

KS D ISO 9587-2012 金属和其他无机覆层.减少氢脆风险的铁或钢的预处理

简介:이 표준은 고강도의 강에 대하여 후속 전처리, 전기 도금, 자기 촉매 도금, 화성 전처리

信息:ICS:25.220.20;25.220.40 CCS:A29 发布:2012-06-01 实施:2012-06-01

ASTM F1940-07a(2019) 用于防止镀层或涂层紧固件中的氢脆化的过程控制验证的标准测试方法

简介:

信息:ICS:21.060.01 CCS: 发布:2019-08-01 实施:

MH/T 6039-2015 电镀工艺和飞机用化学品的机械氢脆评估试验方法

简介:本标准规定了电镀工艺和飞机用化学品导致机械氢脆的评估试验方法。本标准适用于电镀工艺和飞机用化学品导致机械氢脆的评估试验。

信息:ICS:19 CCS:A21 发布:2015-04-08 实施:2015-08-01

KS D ISO 9588-2012 金属和其他无机涂层.为减轻氢脆危险的铁和钢的后包覆处理

简介:이 표준은 표면 처리 공정에서 일어날 수 있는 수소 취성의 민감성이나 민감도를 감소시키기

信息:ICS:25.220.40;25.220.20 CCS:A29 发布:2012-06-01 实施:2012-06-01

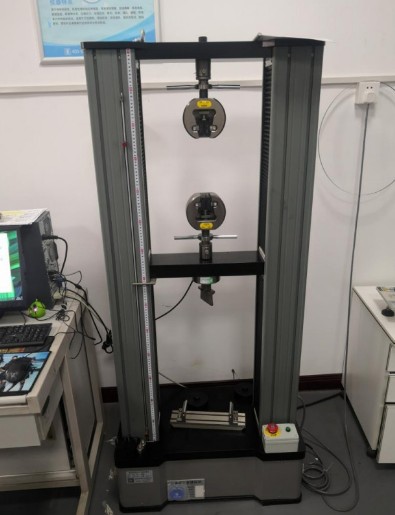

北检院部分仪器展示

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +