蒸发损失检测标准相关信息

GB/T 11964-2008 石油沥青蒸发损失测定法

简介:本标准规定了测定石油沥青在规定条件下加热时的质量(不包括水)变化。本标准适用于石油沥青。本标准未涉及有关使用的安全规定,标准使用者有责任在使用前制定合适的安全应用规程。

信息:ICS:75.140 CCS:E43 发布:2008-02-13 实施:2008-09-01

ASTM D5800-15 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2015-04-01 实施:

ASTM D5800-04a 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2004-11-01 实施:

GB/T 11964-1989 石油沥青蒸发损失测定法

简介: 本标准规定了用重量法测定石油沥青在规定条件下加热时的蒸发损失。 本标准适用于测定石油沥青。

信息:ICS:75.140 CCS:E43 发布:1989-12-23 实施:1990-11-01

ASTM D5800-14e2 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2014-10-01 实施:

ASTM D5800-04 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2004-05-01 实施:

GB 7325-1987 润滑脂和润滑油蒸发损失测定法

简介:

信息:ICS: CCS:E36 发布:1987-02-27 实施:1988-03-01

ASTM D5800-14 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2014-10-01 实施:

SH/T 0731-2004 润滑油蒸发损失测定法(热重诺亚克法)

简介:

信息:ICS:75.100 CCS:E34 发布:2004-04-09 实施:2004-09-01

GB/T 7325-1987 润滑脂和润滑油蒸发损失测定法

简介: 本方法适用于测定润滑脂和润滑油的蒸发损失。这些润滑剂在使用时蒸发损失为一项重要因素。蒸发损失可以在99~150℃的任一温度下进行测定。

信息:ICS:75.100 CCS:E36 发布:1987-02-27 实施:1988-03-01

ASTM D5800-14e1 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2014-10-01 实施:

ASTM D5800-2004 用NOACK法测定润滑油蒸发损失的标准试验方法

简介:1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils). Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Woods metal Noack evaporative apparatus; and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions but may be readily adapted to other conditions when required.1.2 Noack results determined using Procedures A and B show consistent differences. Procedure A gives slightly lower results versus Procedure B on formulated engine oils, while Procedure A gives higher results versus Procedure B on basestocks.1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E34 发布:2004 实施:

ASTM D2595-22 宽温度范围内润滑脂蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2022-12-01 实施:

ASTM D6375-09(2014) 热重分析仪对润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2014-05-01 实施:

ASTM D5800-2004a 用NOACK法测定润滑油蒸发损失的标准试验方法

简介:1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils). Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Woods metal Noack evaporative apparatus; and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions but may be readily adapted to other conditions when required.1.2 Noack results determined using Procedures A and B show consistent differences. Procedure A gives slightly lower results versus Procedure B on formulated engine oils, while Procedure A gives higher results versus Procedure B on basestocks.1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E34 发布:2004 实施:

ASTM D972-22 润滑脂和油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2022-12-01 实施:

GOST 32334-2013 润滑油. 采用热重量分析仪 (TGA) Noack法测定蒸发损失

简介:

信息:ICS:75.100 CCS: 发布:2013 实施:2015-01-01

KS M 2453-2003 润滑油蒸发损失测定法.NOACK法

简介:1.1 이 규격은 NOACK 증발 시험 장치를 사용하여 윤활유(특히 엔진 오일)의 증발

信息:ICS:75.100 CCS:G15 发布:2003-12-05 实施:2003-12-05

ASTM D5800-21 用诺克法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2021-10-01 实施:

DIN 51581-1-2011 石油产品检验.蒸发损失测定.第1部分:Noack试验

简介:

信息:ICS:75.080 CCS:E30 发布:2011-09 实施:

KS M 2453-2003 润滑油蒸发损失测定法.NOACK法

简介:1.1 이 규격은 NOACK 증발 시험 장치를 사용하여 윤활유(특히 엔진 오일)의 증발

信息:ICS:75.100 CCS:G15 发布:2003-12-05 实施:2003-12-05

ASTM D5800-20 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2020-05-01 实施:

DIN 58397-1-2011 光学工程产品.精密机械和光学仪器用润滑脂的检验.第1部分:蒸发损失

简介:

信息:ICS:37.020;75.100 CCS:E36 发布:2011-07 实施:

KS M 2453-2003(2018) 对于通过Noack法测定润滑油蒸发损失的测试方法

简介:

信息:ICS:75.100 CCS: 发布:2003-12-05 实施:

ASTM D5800-19a 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2019-12-15 实施:

NB/SH/T 0059-2010 润滑油蒸发损失的测定 诺亚克法

简介:1.1本标准规定了测定润滑油蒸发损失的两种方法。A法采用伍德合金诺亚克蒸发损失测定仪,B法采用自动的非伍德合金诺亚克蒸发损失测定仪。本标准的试验方法与操作条件相关,但如果需要也适用于其他条件。1.2 A法和B法的测定结果存在差异。对全配方内燃机油,A法的测定结果略低于B法的测定结果;对基础油,A法的测定结果略高于B法的测定结果。1.3本标准采用[SI]国际单位制单位。1.4本标准涉及某些有危险性的材料、操作和仪器,但并未对此有关的所有安全问题都提出建议。因此,用户在使用本标准之前有必要建立适当的安全和防护措施,并确定相关规章限制的适用性。

信息:ICS:75.100 CCS:E34 发布:2011-01-09 实施:2011-05-01

ASTM D5800-03a 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2003-12-01 实施:

ASTM D6375-09(2019) 用热重分析仪(TGA)Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2019-12-01 实施:

ASTM D5800-10 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2010-08-01 实施:

ASTM D5800-03 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2003-03-10 实施:

ASTM D5800-19 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2019-07-01 实施:

ASTM D5800-2010 Noack法测定润滑油的蒸发损失的标准试验方法

简介:The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate. Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil. Many engine manufacturers specify a maximum allowable evaporation loss. Some engine manufacturers, when specifying a maximum allowable evaporation loss, quote this test method along with the specifications. Procedure C, using the Selby-Noack apparatus, also permits collection of the volatile oil vapors for determination of their physical and chemical properties. Elemental analysis of the collected volatiles may be helpful in identifying components such as phosphorous, which has been linked to premature degradation of the emission system catalyst.1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils). Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Woods metal Noack evaporative apparatus; and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions but may be readily adapted to other conditions when required. 1.2 Noack results determined using Procedures A and B show consistent differences. Procedure A gives slightly lower results versus Procedure B on formulated engine oils, while Procedure A gives higher results versus Procedure B on basestocks. 1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 CCS:E34 发布:2010 实施:

DIN 51581-1-2003 石油产品检验.蒸发损失测定.第1部分:NOACK试验

简介:This standard describes the determination of the evaporation loss of expressed as % mass loss of straight mineral and inhibited lubricating oils (especially engine oils) at temperatures up to 350GradC.

信息:ICS:75.080 CCS:E30 发布:2003-02 实施:

ASTM D5800-18a 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2018-06-15 实施:

ASTM D6375-09 用热重分析仪(TGA)Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2009-03-01 实施:

ASTM D972-02 润滑油和油脂蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2002-04-10 实施:

ASTM D5800-18 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2018-05-01 实施:

ASTM D6375-2009 用热重分析器(TGA)Noack法对润滑油蒸发损失的试验方法

简介:This test method is a safe and fast alternative for determination of the Noack evaporation loss of a lubricant. The evaporation loss of a lubricant is important in the hot zones of equipment where evaporation of part of the lubricant may increase lubricant consumption. Some lubricant specifications cite a maximum allowable evaporative loss.1.1 This test method covers the procedure for determining the Noack evaporation loss of lubricating oils using a thermogravimetric analyzer test (TGA). The test method is applicable to base stocks and fully formulated lubricant oils having a Noack evaporative loss ranging from 0 to 30 mass %. This procedure requires much smaller specimens, and is faster when multiple samples are sequentially analyzed, and safer than the standard Noack method using Wood's metal. 1.2 The evaporative loss determined by this test method is the same as that determined using the standard Noack test methods. 1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E34 发布:2009 实施:

ASTM D972-97 润滑油和油脂蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2002-04-10 实施:

KS M 2037-2017 测试方法润滑油脂蒸发损失

简介:

信息:ICS:75.140 CCS: 发布:2017-12-27 实施:

ASTM D972-02(2008) 润滑油和油脂蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2008-05-01 实施:

ASTM D972-2002(2008) 润滑脂和润滑油蒸发损失的标准试验方法

简介:The loss of volatile materials from greases and oils can adversely effect the original performance characteristics of a lubricant and therefore could be a significant factor in evaluating a lubricant for a specific use. Such volatiles can also be considered contaminants in the environment in which the lubricant is to be used. Correlation between results from this test method and service performance has not been established. The test can be run at any agreed upon temperature between 100 and 150x00B0;C (210 to 300x00B0;F). Note 18212;The specified flow of air, 2.58 x00B1; 0.02 g/min, (2 L/min at standard temperature and pressure), assumes dry air. It is not known that the original work involved dry air but it has since been shown that this can be a factor in reproducibility and should be addressed. A dew point of less than 10x00B0;C at standard temperature and pressure will be satisfactory. Note 28212;To determine evaporation loss at temperatures above 150x00B0;C (300x00B0;F), see Test Methods D 2595.1.1 This test method covers the determination of the loss in mass by evaporation of lubricating greases and oils for applications where evaporation loss is a factor. Evaporation loss data can be obtained at any temperature in the range from 100 to 150x00B0;C (210 to 300x00B0;F). 1.2 The values stated in SI units are to be regarded as standard. The values in given in parentheses are for information only. 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E30 发布:2002 实施:

KS M 2037-2017(2022) 润滑脂蒸发损失试验方法

简介:

信息:ICS:75.140 CCS: 发布:2017-12-27 实施:

ASTM D2595-96(2008) 润滑油在宽温度范围内蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2008-05-01 实施:

ASTM D972-2002 润滑脂和润滑油蒸发损失的标准试验方法

简介:The loss of volatile materials from greases and oils can adversely effect the original performance characteristics of a lubricant and therefore could be a significant factor in evaluating a lubricant for a specific use. Such volatiles can also be considered contaminants in the environment in which the lubricant is to be used. Correlation between results from this test method and service performance has not been established. The test can be run at any agreed upon temperature between 100 and 150x00B0;C (210 to 300x00B0;F). Note 18212;The specified flow of air, 2.58 x00B1;0.02 g/min, (2L/min at standard temperature and pressure), assumes dry air. It is not known that the original work involved dry air but it has since been shown that this can be a factor in reproducibility and should be addressed. A dew point of less than 10x00B0;C at standard temperature and pressure will be satisfactory. Note 28212;To determine evaporation loss at temperatures above 150x00B0;C (300x00B0;F), see Test Methods D 2595.1.1 This test method covers the determination of the loss in mass by evaporation of lubricating greases and oils for applications where evaporation loss is a factor. Evaporation loss data can be obtained at any temperature in the range from 100 to 150176C (210 to 300176F). 1.2 The values stated in either SI units or inch-pound units shall be regarded separately as standard. The values stated in each system may not be exact equivalents of the other; therefore each system must be used independently of the other, without combining values in any way. 1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E34 发布:2002 实施:

ASTM D2595-17 润滑油在宽温度范围内蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2017-06-01 实施:

ASTM D5800-08 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2008-05-01 实施:

ASTM D5800-00a 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS: CCS: 发布:2000-08-10 实施:

ASTM D2595-2017 润滑脂在宽温域下蒸发损失的标准试验方法

简介: 5.1x00a0;The loss of volatile materials from greases and oils can adversely affect the original performance characteristics of a lubricant and, therefore, could be a significant factor in evaluating a lubricant for a specific use. Such volatiles can also be considered contaminants in the environment in which the lubricant is to be used. Correlation between results from this test method and service performance has not been established. 5.2x00a0;The test method can be used at any specified temperature between 938201;x00b0;C and 3168201;x00b0;C (2008201;x00b0;F and 6008201;x00b0;F) that may be agreed upon by the user of the method. (Warningx2014;This test method should not be used at temperatures which exceed the flash point of the base oil of the grease.) Note 1:x00a0;The specified flow of air, 2.588201;g/min x00b1; 0.028201;g/min, (28201;L/min at standard temperature and pressure), assumes dry air. It is not known that the original work involved dry air but it has since been shown that this can be a factor in reproducibility and should be addressed. Air with a dew point of less than 108201;x00b0;C at standard temperature and pressure will be satisfactory. 1.1x00a0;This test method covers the determination of evaporation loss of lubricating greases at temperatures between 938201;x00b0;C and 3168201;x00b0;C (2008201;x00b0;F and 6008201;x00b0;F). This test method is intended to augment Test Method D972, which is limited to 1498201;x00b0;C (3008201;x00b0;F). 1.2x00a0;The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only. 1.3x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety information, see 5.2. 1.4x00a0;This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

信息:ICS:75.100 CCS:E34 发布:2017 实施:

ASTM D6375-05 用热重分析仪(TGA)Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2005-06-01 实施:

ASTM D5800-00ae1 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2000-08-10 实施:

ASTM D972-16 润滑油和油脂蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2016-04-01 实施:

ASTM D5800-05 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2005-06-01 实施:

ASTM D5800-2000a 用NOACK法测定润滑油蒸发损失的标准试验方法

简介:1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils). Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Wood's metal Noack evaporative apparatus, and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions but may be readily adapted to other conditions when required.1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Sections 8 and 18 and 6.1.1, 7.1, 7.5, 9.1, 10.3, and 17.1 for specific precautionary statements.

信息:ICS: CCS:E34 发布:2000 实施:

ASTM D972-2016 润滑脂和润滑油蒸发损失的标准试验方法

简介: 5.1x00a0;The loss of volatile materials from greases and oils can adversely effect the original performance characteristics of a lubricant and therefore could be a significant factor in evaluating a lubricant for a specific use. Such volatiles can also be considered contaminants in the environment in which the lubricant is to be used. Correlation between results from this test method and service performance has not been established. 5.2x00a0;The test can be run at any agreed upon temperature between 1008201;x00b0;C and 1508201;x00b0;C (2108201;x00b0;F to 3008201;x00b0;F). Note 1:x00a0;The specified flow of air, 2.588201;g/min x00b1; 0.028201;g/min, (28201;L/min at standard temperature and pressure), assumes dry air. It is not known that the original work involved dry air but it has since been shown that this can be a factor in reproducibility and should be addressed. A dew point of less than 108201;x00b0;C at standard temperature and pressure will be satisfactory. Note 2:x00a0;To determine evaporation loss at temperatures above 1508201;x00b0;C (3008201;x00b0;F), see Test Methods D2595. 1.1x00a0;This test method covers the determination of the loss in mass by evaporation of lubricating greases and oils for applications where evaporation loss is a factor. Evaporation loss data can be obtained at any temperature in the range from 1008201;x00b0;C to 1508201;x00b0;C (2108201;x00b0;F to 3008201;x00b0;F). 1.2x00a0;The values stated in SI units are to be regarded as standard. 1.2.1x00a0;Exceptionx2014;The values given in parentheses are for information only. 1.3x00a0;This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 CCS: 发布:2016 实施:

ASTM D5800-2005 用Noack法测定润滑油蒸发损失的标准试验方法

简介:The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate. Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil. Many engine manufacturers specify a maximum allowable evaporation loss. Some engine manufacturers, when specifying a maximum allowable evaporation loss, quote this test method along with the specifications. Procedure C, using the Selby-Noack apparatus, also permits collection of the volatile oil vapors for determination of their physical and chemical properties. Elemental analysis of the collected volatiles may be helpful in identifying components such as phosphorous, which has been linked to premature degradation of the emission system catalyst.1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils). Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Woods metal Noack evaporative apparatus; and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions but may be readily adapted to other conditions when required.1.2 Noack results determined using Procedures A and B show consistent differences. Procedure A gives slightly lower results versus Procedure B on formulated engine oils, while Procedure A gives higher results versus Procedure B on basestocks.1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E34 发布:2005 实施:

ASTM D5800-2000ae1 用NOACK法测定润滑油蒸发损失的标准试验方法

简介:1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils). Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Wood's metal Noack evaporative apparatus, and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions but may be readily adapted to other conditions when required.1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Sections 8 and 18 and 6.1.1, 7.1, 7.5, 9.1, 10.3, and 17.1 for specific precautionary statements.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E34 发布:2000 实施:

ASTM D5800-15a 用Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:2015-07-01 实施:

ASTM D6375-2005 用热重分析仪(TGA)Noack法测定润滑油蒸发损失的标准试验方法

简介:This test method is a safe and fast alternative for determination of the Noack evaporation loss of a lubricant. The evaporation loss of a lubricant is important in the hot zones of equipment where evaporation of part of the lubricant may increase lubricant consumption. Some lubricant specifications cite a maximum allowable evaporative loss.1.1 This test method covers the procedure for determining the Noack evaporation loss of lubricating oils using a thermogravimetric analyzer test (TGA). The test method is applicable to base stocks and fully formulated lubricant oils having a Noack evaporative loss ranging from 0 to 30 mass %. This procedure requires much smaller specimens, and is faster when multiple samples are sequentially analyzed, and safer than the standard Noack method using Wood's metal.1.2 The evaporative loss determined by this test method is the same as that determined using the standard Noack test methods.1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

信息:ICS:75.100 (Lubricants, industrial oils and related pr CCS:E34 发布:2005 实施:

ASTM D6375-99a 用热重分析仪(TGA)Noack法测定润滑油蒸发损失的标准试验方法

简介:

信息:ICS:75.100 CCS: 发布:1999-06-10 实施:

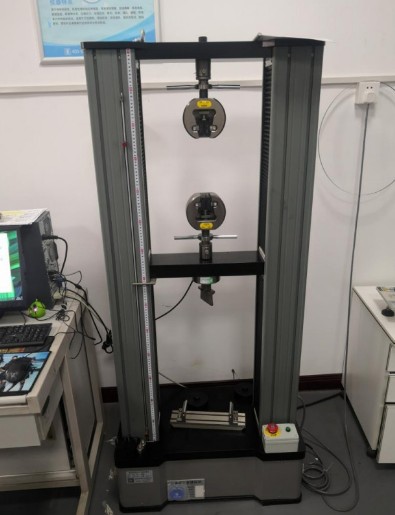

北检院部分仪器展示

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +

北检(北京)检测技术研究院(简称:北检院),依托科研测试与材料检测重点领域,结合“211工程”和“985工程”建设,面向学校和社会企业开放的仪器共享机构和跨学科检测交叉融合平台。面向企业及科研单位跨学科研究、面向社会公共服务,构建具有装备优势、人才优势和服务优势的综合科研检测服务平台。

了解更多 +